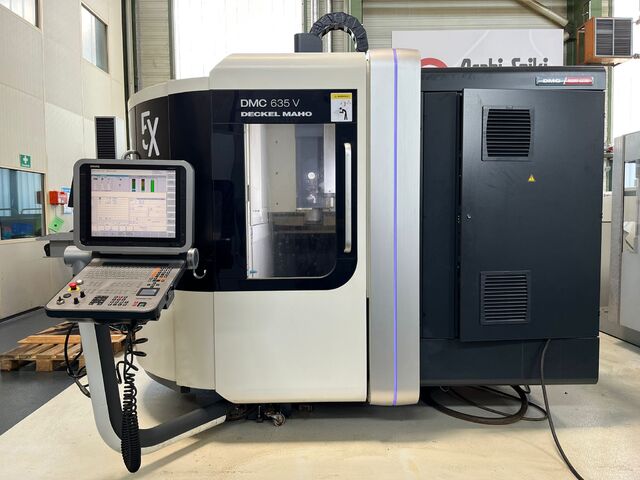

Vertical machining center

Vertical machining centerYear: 2013

Heidenhain iTNC 530, Year, X: 635, Y: 510, Z: 460, [rpm] 10.000, Tool: SK 40, Toolchanger, Tools 30, Pal. 2, Table: 560 x 790- Universal machining center

Year: 2008

Siemens 840 D ShopMill, Year 2008, X: 1.760 (2 x 630), Y: 600, Z: 800 horizontal oder 770 vertikal, A-Axes, B-Axes +/- 100°, hydraulisch geklemmt, stufenlos interpolierend, Axes 5, [rpm] 30 - 6.000, kW 30, [Nm] 143, Tool: SK 40, Toolchanger, Tools 36, NC rotary table AXA RTA 4L-520, Tailstock manuell, Spitzenhöhe 280 mm, Int. cooling [bar] 30, cooling system - Universal machining center

Year: 2003

Heidenhain TNC 430, Year 2003, X: 2.300, Y: 1.200, Z: 600, [rpm] 30 - 10.000, kW 40/25, [Nm] 254 / 159, Tool: SK 40, Tools 60, Table: 1.100 x 1.100, NC rotary table 1.100 x 1.100 - Horizontal machining center

Year: 2006

Siemens 840D powerline + Shopmill, Year 2006, X: 1.000, Y: 1.000, Z: 1.000, [rpm] 8.000, Tool: HSK 100, Tools 270 / 360, Pal. 2, Pal. size 800 x 800, B-Axes 0,001°, Oil mist separator, Int. cooling [bar] 40 - Horizontal machining center

Year: 2005

Siemens 840D powerline + Shopmill, Year 2005, X: 1.000, Y: 1.000, Z: 1.000, [rpm] 8.000, Tool: HSK 100, Tools 270 / 360, Pal. 2, Pal. size 800 x 800, B-Axes 0,001°, Oil mist separator, Int. cooling [bar] 40 - Universal machining center

Year: 2004

Heidenhain iTNC 530, Year 2004, X: 1.800, Y: 2.000, Z: 1.100, B-Axes -7 / +187 °, C-Axes 360 °, Axes 5, [rpm] 18.000, kW 28 /19, [Nm] 121, Tool: HSK 63, Toolchanger, Tools 120, Pal. 2, Pal. size 1.600 x 1.400, Int. cooling [bar] 40 - Universal machining center

Year: 2007

Siemens 840 D, Year 2007, X: 780, Y: 560, Z: 560, B-Axes +30 / -120°, C-Axes, [rpm] 12.000, Tool: SK 40, Toolchanger Kettenmagazin / chain magazine, Tools 180, NC rotary table, Pal. size 630 x 500, Pal. 5, cooling system, Int. cooling [bar] 40 - Vertical machining center

Year: 2006

Heidenhain iTNC 530, Year 2006, X: 635, Y: 460, Z: 510, [rpm] 20 - 10.000, [kW] 9 / 13, Tool: SK 40, Toolchanger, Tools 20, Table: 790 x 560 - Vertical machining center

Year: 2008

Sinumerik 840 D, Year 2008, X: 635, Y: 510, Z: 460, [rpm] 20 - 10.000, [kW] 9 / 13, Tool: SK 40, Toolchanger, Tools 20, Table: 790 x 560  Vertical machining center

Vertical machining centerYear: 2013

Heidenhain iTNC 530, Year, X: 635, Y: 510, Z: 460, [rpm] 10.000, Tool: SK 40, Toolchanger, Tools 30, Pal. 2, Table: 560 x 790- Universal machining center

Year: 2017

Siemens 840 D Operate, Year 2017, Axes 5, X: 2.600, Y: 1.100, Z: 900, B-Axes, C-Axes, [rpm] 20 - 15.000, kW 46 / 30, [Nm] 200 / 130, Tool: SK 40, Toolchanger, Tools 60, NC rotary table Ø 1.050 Integriert, Table: 3.200 x 1.100, Int. cooling [bar] 40, 600 l

Haven't found the right machine?

Contact us - we will find the right machine for you!

Used Milling Machines at Stenzel

If you are looking to buy used milling machines, Stenzel is the right partner for you. We offer a wide selection of used milling machines in good condition at attractive prices. We will advise you in detail and find the right machine for your needs.

Buying advice: How to find the right milling machine

If you're buying a used milling machine, you should do your research beforehand to find the right model for your needs. This buyer's guide will help you make the right decision.

Checklist: What you should look out for when buying a CNC milling machine

Before you invest, you should check various points in detail. A clear checklist will help you make the right choice:

- Check condition: Is there any visible wear or technical defects?

- Ensure compatibility: Does the machine match your software and production environment?

- Arrange a test run: This is the only way to realistically assess precision and function.

- Consider additional costs: Don't forget transportation, installation and possible retrofits.

- Choose a reputable provider: Look for guarantees and a reliable dealer.

This will help you avoid bad purchases and ensure that you get a machine that meets your requirements in the long term.

CNC milling machine explained simply: definition & meaning

A CNC milling machine is a computer-controlled machine tool that processes workpieces made of materials such as metal, plastic or wood with millimetre precision. The abbreviation CNC stands for Computerized Numerical Control - a control technology that automates processes and thus enables consistently high quality

.The use of CNC technology allows errors to be reduced, tolerances to be reliably maintained and product standards to be permanently secured. As a result, CNC machines have become indispensable in industries such as metalworking, mold making and woodworking.

How does a CNC milling machine work? Structure & mode of operation

Main components of a CNC milling machine

- Spindle: holds the tool and ensures the right speed

- Milling table: fixes the workpiece during processing.

- Axes: move the tool and workpiece in the X, Y and Z directions.

Process steps of CNC machining

- Programming the machine: via CAM software.

- Material processing: using rotating milling tools.

- Automatic control: to ensure exact results.

The result is workpieces with consistently high accuracy - even in series production.

Where are CNC milling machines used? Typical applications

CNC milling machines are versatile and can be used in almost all areas of industry:

- Metal processing: Production of machine components, tools and prototypes .

- Woodworking: Production of furniture parts and decorative elements.

- Automotive industry: Production of engine components, body parts and tools.

- Medical technology: Development of implants, surgical instruments and devices.

- Aerospace: Machining of complex components with tight tolerances.

Types of CNC milling: 3-axis, 4-axis, 5-axis & more

3-axis milling machines

In 3-axis milling machines, the tool moves along the X, Y and Z axes. This design is particularly suitable for standard machining operations such as drilling holes, grooves or simple contours. It is often used with vertical milling machines.</p

4-axis milling machines

4-axis milling machines add an additional rotational axis, usually the A or B axis, to the classic 3-axis machining process. This means that workpieces can also be machined laterally - ideal for more complex geometries or cylindrical parts. They are available in both vertical and horizontal versions.

5-axis milling machines

5-axis milling machines offer maximum flexibility: In addition to the movements in X, Y and Z, two rotation axes can be controlled. This means that even complicated free-form surfaces and components with tight tolerances are possible. These machines are available as vertical machining centers and as horizontal milling machines, depending on the area of application.</p

Vertical milling machines

Vertical milling machines have a vertical spindle. They are particularly suitable for processing flat surfaces, pockets or contours. They are typically used as 3- or 4-axis models, and also as state-of-the-art 5-axis machining centers if required.</p

Horizontal milling machines

The spindle of horizontal milling machines is arranged horizontally. This means that even large and heavy workpieces can be processed efficiently. This design is often used as a 4- or 5-axis machine and is particularly suitable for deep cavities or complex components in series production.</p

Used milling machines - costs at a glance

The prices for used milling machines vary greatly. Several factors are decisive:

- Model: Standard machines are cheaper than specialized systems.

- Size: The larger the processing area, the higher the acquisition costs.

- Functionality: Extra features such as 5-axis machining increase the price.

- Manufacturers: Brands such as DMG, Doosan or Hermle are more expensive, but often offer a longer service life.

Entry-level models are available from around €500. Specialized high-end machines, on the other hand, can cost several hundred thousand euros.</p

Why a used CNC milling machine is worthwhile

Buying a used milling machine offers several advantages:</p

- Cost savings: significantly cheaper than new machines and less depreciation

- Fast availability: immediately ready for use, no long delivery times.

- Tested quality: frequently serviced or retrofitted, ready for immediate use.

- Sustainability: Reuse reduces resource consumption and CO₂ emissions.

This makes a used CNC milling machine an attractive choice not only economically but also ecologically.

Tips for buying a used machine tool

If you want to buy a used milling machine, you should prepare well:

- Define your requirements in advance (materials, sizes, functions).

- Only buy from reputable specialist retailers who offer advice and a guarantee

- Check the maintenance status, possible retrofits and existing documentation.</li

This will ensure that the machine works reliably in the long term.</p

Stenzel: Your partner for used CNC and machine tools

Stenzel GmbH has been a specialist in machine tools for over 100 years. With our experience and wide range of products, we are your reliable partner when buying a used milling machine

- Fair prices

- Extensive selection from renowned manufacturers (e.g. DMG, Hermle, Mori Seiki)

- Technically tested quality - ready for immediate use

- Individual advice & service

Contact us today - by phone or email.

FAQ - Answers about used CNC milling machines

What does a used CNC milling machine cost?

Prices start at around €500 and can reach several hundred thousand euros for complex 5-axis machines.

Is it worth buying a used milling machine?

Yes, because you save costs, get tested quality and benefit from immediate availability.

Which manufacturers are particularly popular?

The most popular include DMG, Hermle, Mori Seiki, Doosan and Trumpf.

How do I find the right milling machine for my business?

Define your requirements such as material, processing sizes and range of functions. Our experts will advise you on your selection.

Is there a warranty on used CNC milling machines?

Yes, at Stenzel you get tested machines with a warranty and comprehensive service, so you can invest with confidence.

How quickly can used milling machines be delivered?

Used machines are usually available immediately and can be put into operation without long waiting times.

What advantages do used machines have over new machines?

You benefit from lower acquisition costs, fast availability and a sustainable solution through reuse.