Used vertical milling machines and vertical machining centers

Our offers for vertical milling machines & vertical machining centers

Vertical machining center

Vertical machining centerYear: 2013

Heidenhain iTNC 530, Year 2013, X: 1.100, Y: 610, Z: 610, [rpm] 10.000, [Nm] 332, kW 13, Tool: SK 40, Tools 30, Table: 1.250 x 610, Int. cooling [bar] 22- Vertical machining center

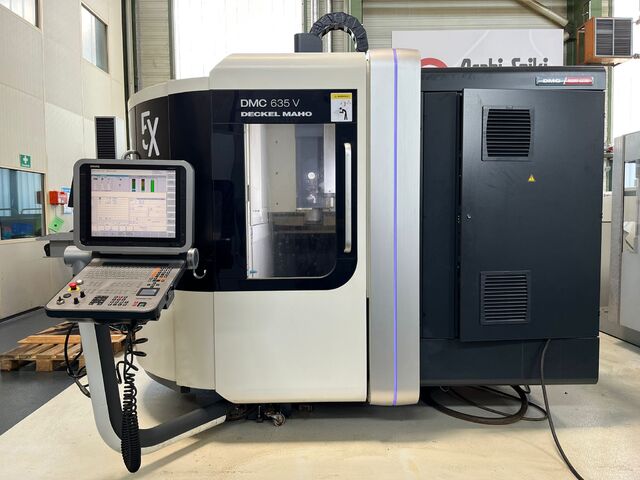

Year: 2006

Heidenhain iTNC 530, Year 2006, X: 635, Y: 460, Z: 510, [rpm] 20 - 10.000, [kW] 9 / 13, Tool: SK 40, Toolchanger, Tools 20, Table: 790 x 560 - Vertical machining center

Year: 2008

Sinumerik 840 D, Year 2008, X: 635, Y: 510, Z: 460, [rpm] 20 - 10.000, [kW] 9 / 13, Tool: SK 40, Toolchanger, Tools 20, Table: 790 x 560  Vertical machining center

Vertical machining centerYear: 2013

Heidenhain iTNC 530, Year, X: 635, Y: 510, Z: 460, [rpm] 10.000, Tool: SK 40, Toolchanger, Tools 30, Pal. 2, Table: 560 x 790- Vertical machining center

Year: 2022

Siemens 828 D, Year 2022, X: 550, Y: 550, Z: 510, [rpm] 12.000, kW 13 / 9, [Nm] 83 (40%), Tool: SK 40, Tools 24, Table: 850 x 650, Int. cooling [bar] 20 - Vertical machining center

Year: 2000

Mitsubishi Meldas control ( G-code programmable), Year, X: 2.000, Y: 1.200, Z: 500, [rpm] 50 - 4.000, [kW] 15, Tool: ISO 50, Tools 20, Table: 2.100 x 1.200 - Vertical machining center

Year: 2008

Andronic 2060, Year 2008, X: 550, Y: 400, Z: 400, [rpm] 0 - 42.000, kW 15 / 17, Tool: HSK 40 E, Tools 32, Table: 650 x 500 - Vertical machining center

Year: 2016

Heidenhain iTNC 530 SmarT.NC, Year 2016, X: 1.500, Y: 700, Z: 810, [rpm] 18.000, [Nm] 162, kW 34, Tool: HSK 63, Tools 40, Table: 1.500 x 800, Int. cooling [bar] 40  Vertical machining center

Vertical machining centerYear: 2013

Heidenhain iTNC 530, Year 2013, X: 1.100, Y: 610, Z: 610, [rpm] 10.000, [Nm] 332, kW 13, Tool: SK 40, Tools 30, Table: 1.250 x 610, Int. cooling [bar] 22

Haven't found the right machine?

Contact us - we will find the right machine for you!

Used Vertical Milling Machines & Vertical Machining Centers at Stenzel

At Stenzel, you'll find used vertical milling machines and vertical machining centers from leading manufacturers at competitive prices. All machines in our inventory are technically inspected and available for viewing. Contact us, and we'll find the perfect machine for your needs.

What are vertical machining centers?

Vertical machining centers belong to the category of metal-cutting machines and are suitable for various tasks such as drilling, milling, threading, and reaming. They are equipped with CNC control, a tool changer, and a tool magazine, allowing fully automated processing of workpieces according to a predefined program.

Operating Principle and Design Types

A vertical machining center operates with a spindle and a movable console, on which the workpiece is clamped and brought to the spindle. Typically, the x- and y-axes are controlled via the table, while the spindle can only move in the z-direction (vertical). Compared to 5-axis milling machines, the spindle is more robustly mounted, so even used vertical machining centers can offer low wear.

Classic design types of vertical machining centers include the console, cross table, moving column, and portal designs, with the latter being particularly common due to its ability to meet high requirements in terms of stability and performance. It also offers advantages when machining very large workpieces.

What Is a Vertical Machining Center Suitable For?

Vertical machining centers are especially suitable for processing flat and box-shaped components. They are frequently used in the production of small and medium series, as well as in workshop manufacturing, and are often the machine of choice for single-part production.

Their fields of application range from mechanical engineering and automotive manufacturing to mold and tool making, as well as specialized applications in medical technology.

Buying a Used Vertical Machining Center

We are your experienced partner when you are looking to buy a used vertical machining center. Our customers benefit from our international network and many years of experience in the used machinery trade. With our optional Stenzel all-inclusive service package, your purchase of a used machine is made as easy as possible.

We take care of everything – from dismantling the vertical machining center on-site, to loading, transport, and installation in your machine hall.