SOLD: Used DMG DMU 75 monoBlock

Universal machining center

DMG DMU 75 monoBlock Milling machine

| Universal machining center | |

| Machine type: | DMG DMU 75 monoBlock |

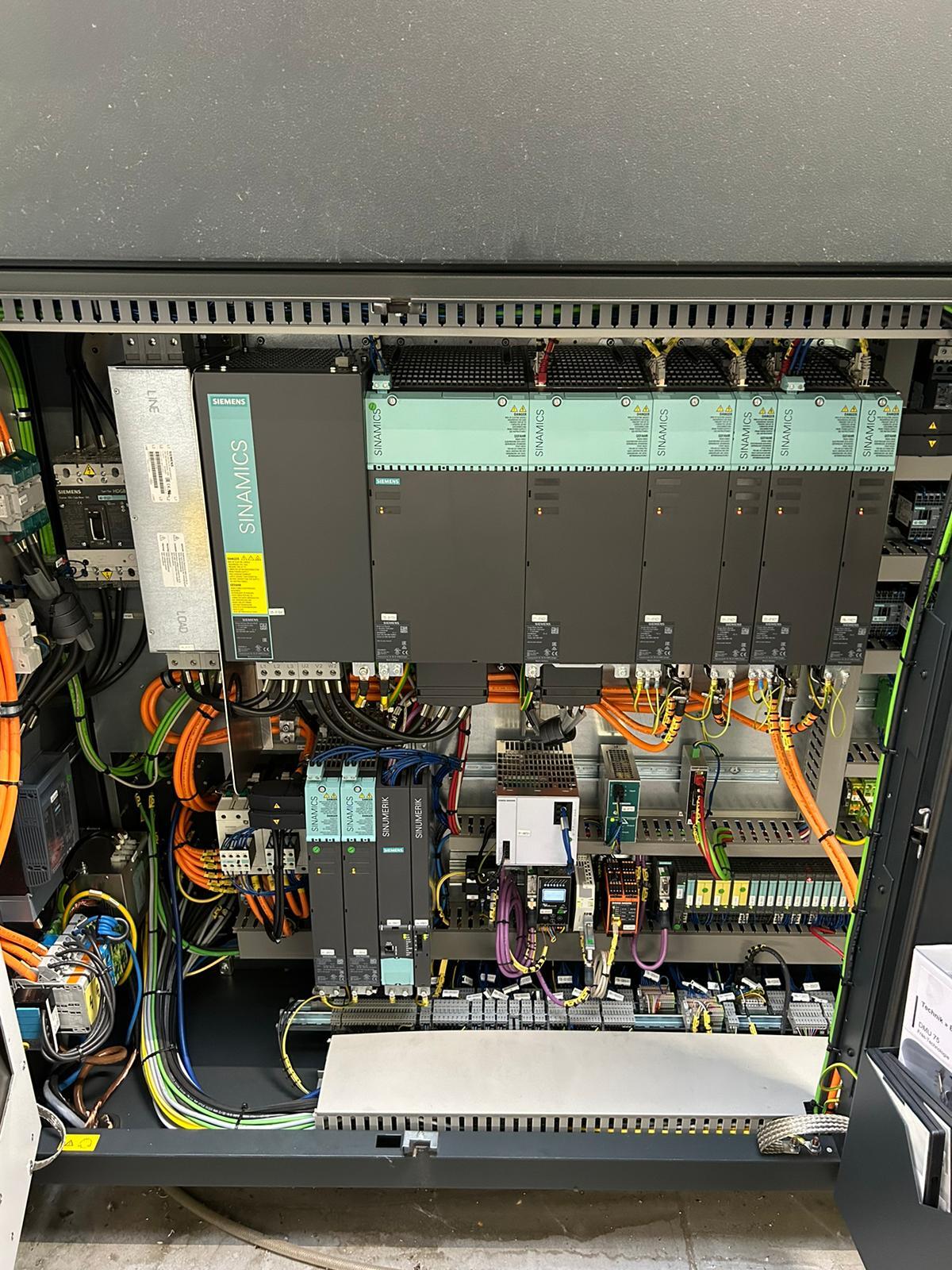

| Control: | Siemens 840 D sl shopmill |

| Year: | 2016 |

| SPECIFICATIONS: | |

| 5-axis-simultaneous | |

| Travel: | |

| X-Axis: [mm] | 750 |

| Y-Axis: [mm] | 650 |

| Z-Axis: [mm] | 560 |

| B-Axes | + / - 120° |

| C-Axis | 360° |

| Amount of controlled axes: | 5 |

| Spindle speeds: [rpm] | 20.000 |

| Spindle power: [kW] | 35 |

| Torque: [Nm] | 130 |

| Tool: | SK 40 |

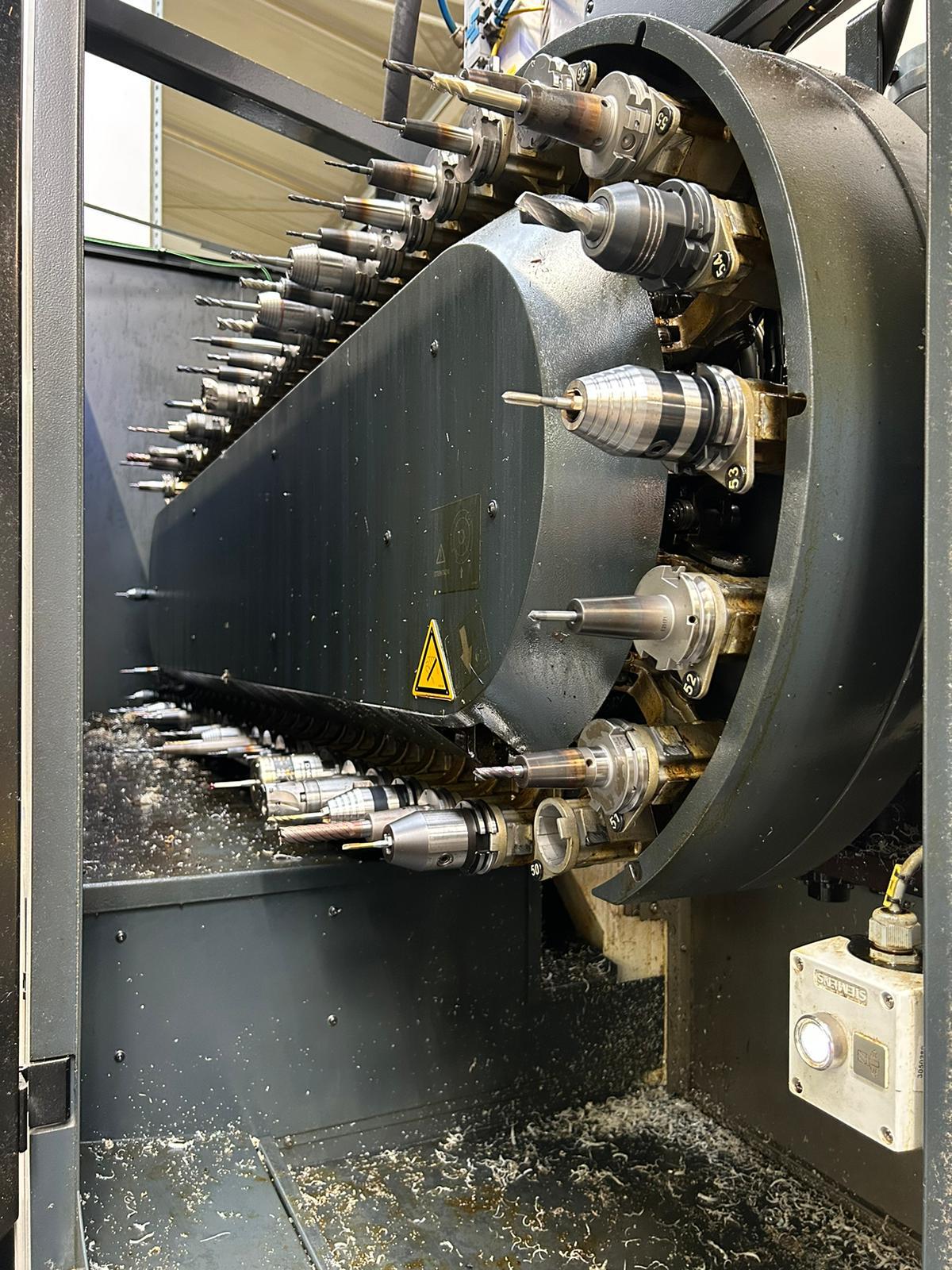

| Toolchanger | |

| Tool capacity: | 60 |

| NC-panning and rotary Table | Ø 650 |

| Table size: [mm] | 800 x 650 |

| Max. Table Load: [kg] | 600 |

| Power consumption: [KW] | 48 kVA |

| Machine weight: [kg] | 12.000 |

| Req. space (LxBxH): [m] | 3,2 x 2,62 x 2,93 |

| Equipment: | |

| Chip conveyor | |

| Internal cooling: [bar] | 40 |

| Caliper | Renishaw |

| Air blow | |

| Electronical handwheel | |

| 3D Quickset | |

| Lastanzeige an Z-Achse | |

| Chip rinsing pistol | |

DMG DMU 75 monoBlock Milling machine

| Universal machining center | |

| Machine type: | DMG DMU 75 monoBlock |

| Control: | Siemens 840 D sl shopmill |

| Year: | 2016 |

| SPECIFICATIONS: | |

| 5-axis-simultaneous | |

| Travel: | |

| X-Axis: [mm] | 750 |

| Y-Axis: [mm] | 650 |

| Z-Axis: [mm] | 560 |

| B-Axes | + / - 120° |

| C-Axis | 360° |

| Amount of controlled axes: | 5 |

| Spindle speeds: [rpm] | 20.000 |

| Spindle power: [kW] | 35 |

| Torque: [Nm] | 130 |

| Tool: | SK 40 |

| Toolchanger | |

| Tool capacity: | 60 |

| NC-panning and rotary Table | Ø 650 |

| Table size: [mm] | 800 x 650 |

| Max. Table Load: [kg] | 600 |

| Power consumption: [KW] | 48 kVA |

| Machine weight: [kg] | 12.000 |

| Req. space (LxBxH): [m] | 3,2 x 2,62 x 2,93 |

| Equipment: | |

| Chip conveyor | |

| Internal cooling: [bar] | 40 |

| Caliper | Renishaw |

| Air blow | |

| Electronical handwheel | |

| 3D Quickset | |

| Lastanzeige an Z-Achse | |

| Chip rinsing pistol | |

DMG DMU 75 monoBLOCK – Powerful 5-Axis Machining Center for Highest Demands

The DMG DMU 75 monoBLOCK is a universal 5-axis machining center, known for its stability, precision, and versatility. It is ideal for medium to large workpieces and complex 5-axis machining tasks. This machine is especially suitable for industries where high accuracy, process reliability, and flexibility are required.

Technical Data of the DMG DMU 75 monoBLOCK at a Glance

Travel Ranges and Workpieces

The DMU 75 monoBLOCK features generous travel ranges of approximately 750 mm in X, 650 mm in Y, and 560 mm in Z. Workpieces up to 840 mm in diameter, around 500 mm in height, and weighing up to 600 kg can be machined effortlessly. Ideal for mold & die, mechanical engineering, aerospace, and medical technology applications.

Spindle and Power

The core of the machine is its high-performance spindle, which – depending on configuration – reaches speeds up to 20,000 RPM with a power output of around 35 kW. This allows precise machining even of demanding materials.

Tool Holder & Magazine

The tool holder is available as HSK-A63 or SK40, often combined with a chain magazine for up to 60 tools. This ensures efficient workflows for medium and large production runs.

Table & Control

The NC swivel rotary table has a diameter of approximately 650 mm and enables precise 5-axis simultaneous machining. The machine is operated via proven controls such as Heidenhain iTNC 640 or Siemens 840D / CELOS. With positioning accuracy of 4 to 5 µm, options such as internal coolant supply up to 40 bar, powerful chip conveyors, and probing systems, the DMU 75 monoBLOCK meets the highest standards in precision and process reliability.

Special Features & Advantages

The monoBLOCK concept is based on a one-piece machine bed made of cast iron. Large guide rollers (e.g., 45 mm) and massive ball screws (Ø 40 / 50 / 40 mm) ensure high stiffness and dynamic stability. The machine requires only about 8 m² of floor space, offers excellent accessibility thanks to its large door opening (approx. 1,310 mm), and can handle workpieces up to 600 kg. Standard features include cooling, compensation, selectable controls, and probing systems – many functions can be automated.

Applications & Industries

- Mold & Die – complex freeform surfaces and mechatronic molds.

- Aerospace – components with high complexity, tight tolerances, and challenging materials.

- Automotive – prototypes, serial components, body parts, and transmission components.

- Medical Technology – implants and instruments requiring high surface quality.

- Mechanical & Plant Engineering – components and assemblies for 5-axis machining, e.g., housings and distributors.

- Energy & Turbine Industry – parts with large radii, complex geometry, or large diameters.

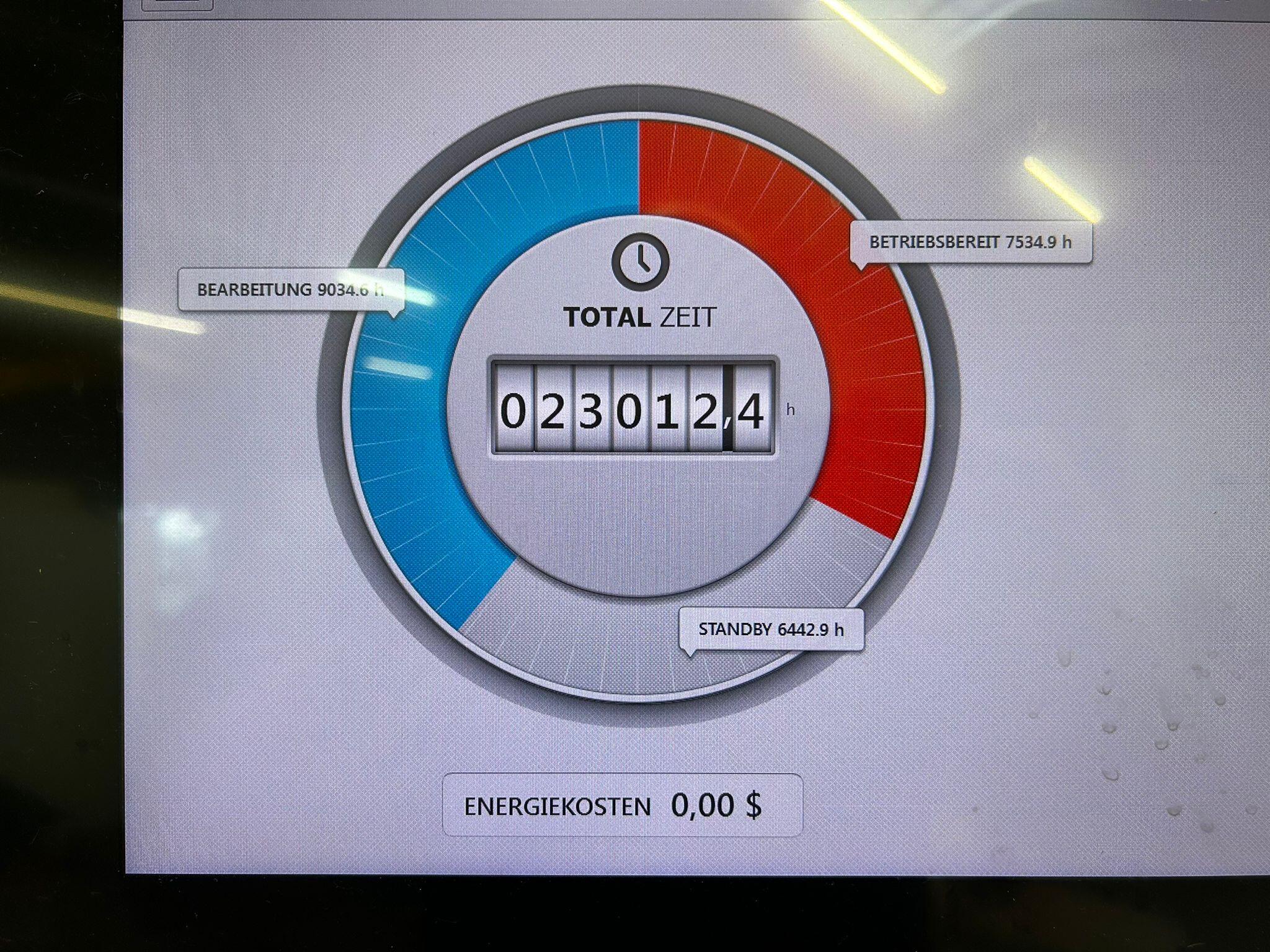

Buying a Used DMG DMU 75 monoBLOCK – an Attractive Option

For those looking to reduce investment costs for a new 5-axis machining center, the market for used DMG DMU 75 monoBLOCK machines offers an interesting option. These machines are known for their longevity, stability, and precision, remaining in high demand even after several years of operation.

Used machine dealers and specialized platforms regularly offer well-maintained units – often including service history and documented machine hours. A used DMU 75 monoBLOCK is particularly suitable for companies looking to quickly expand capacity or acquire a high-performance 5-axis center at a lower entry price.

When purchasing, attention should be paid to spindle hours, the condition of the tool changer, and the control version (Heidenhain or Siemens). With a reliable dealer and an optional maintenance contract, a used machine can be a highly cost-effective alternative to buying new.

Alternatives to the DMU 75 monoBLOCK

Those looking for alternatives will find suitable 5-axis machining centers within DMG MORI's portfolio as well as from other manufacturers. The monoBLOCK series includes models with larger or smaller travel ranges, allowing flexible selection based on workpiece size and performance requirements.

- Hermle C-Series – e.g., model C400, particularly popular in mold & die, offering high precision and excellent guides.

- Mazak Variaxis / Integrex – flexible 5-axis and multi-tasking machines, ideal for serial production and automated solutions.

- GROB – stable and precise 5-axis machines, frequently used in the automotive and aerospace industries.

- Okuma MU-Series – robust machines with advanced thermal compensation, ideal for long machining times and heavy workpieces.

The choice of the right machine depends on available space, required accuracy, automation level, and investment budget.