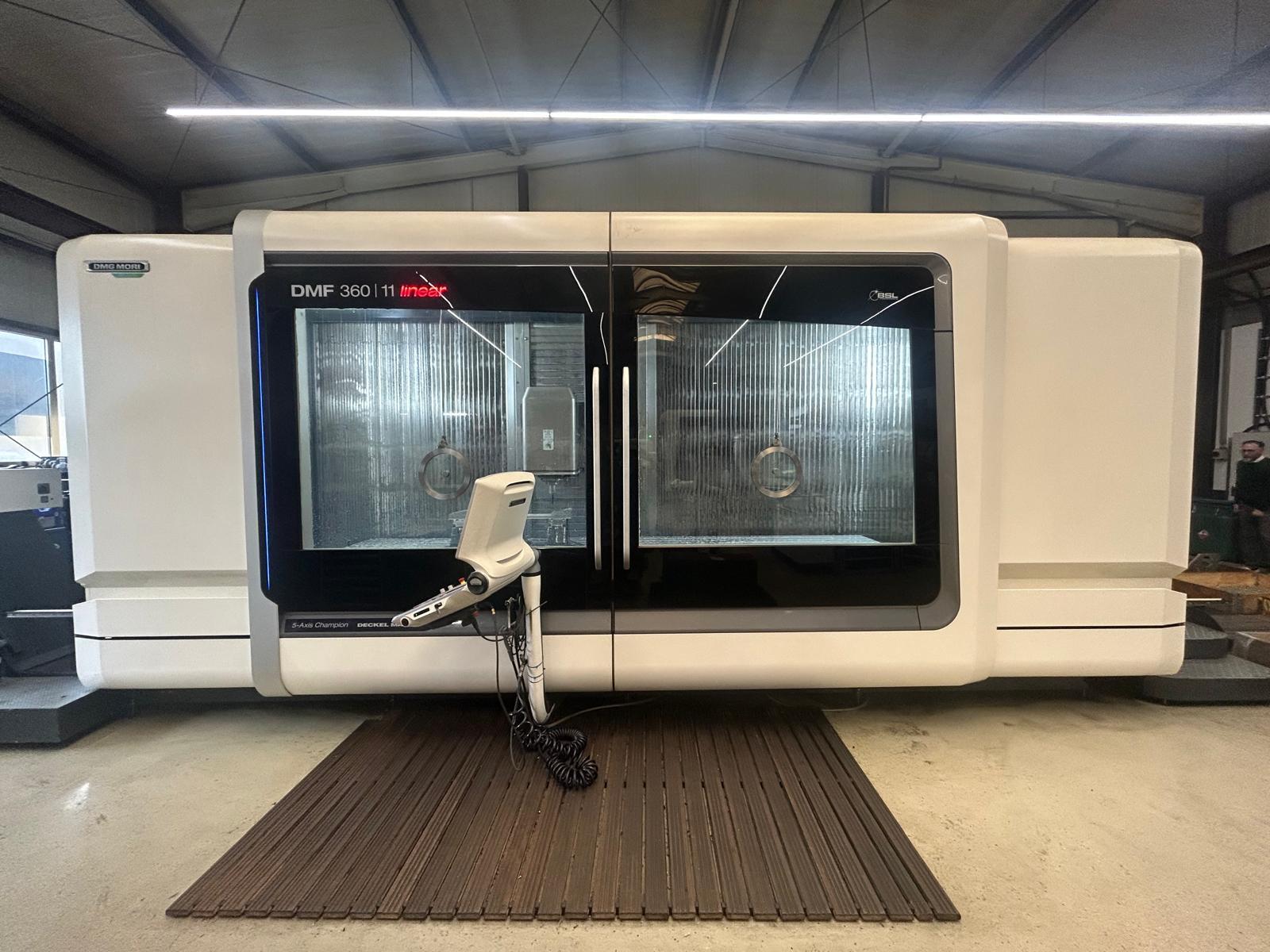

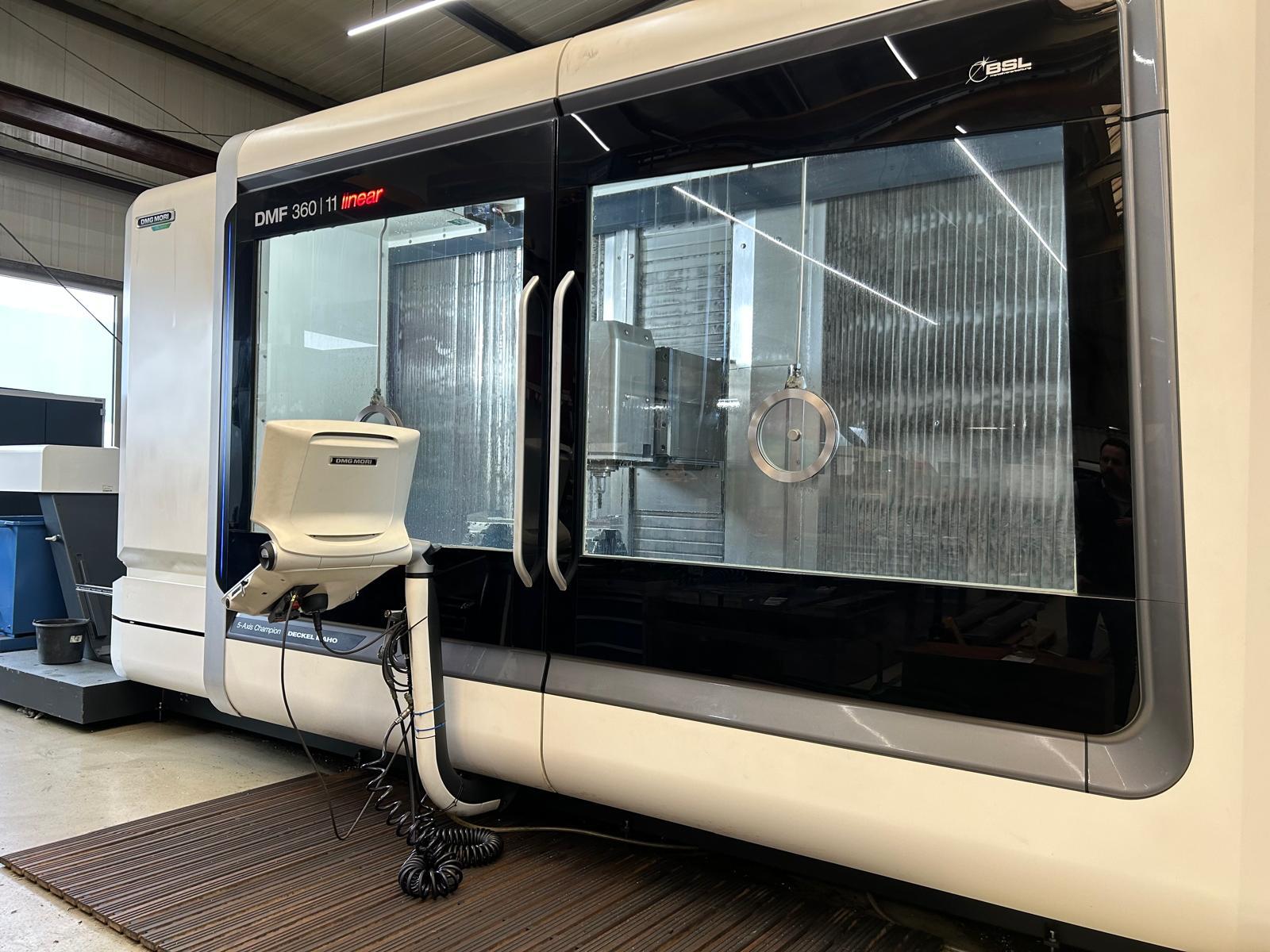

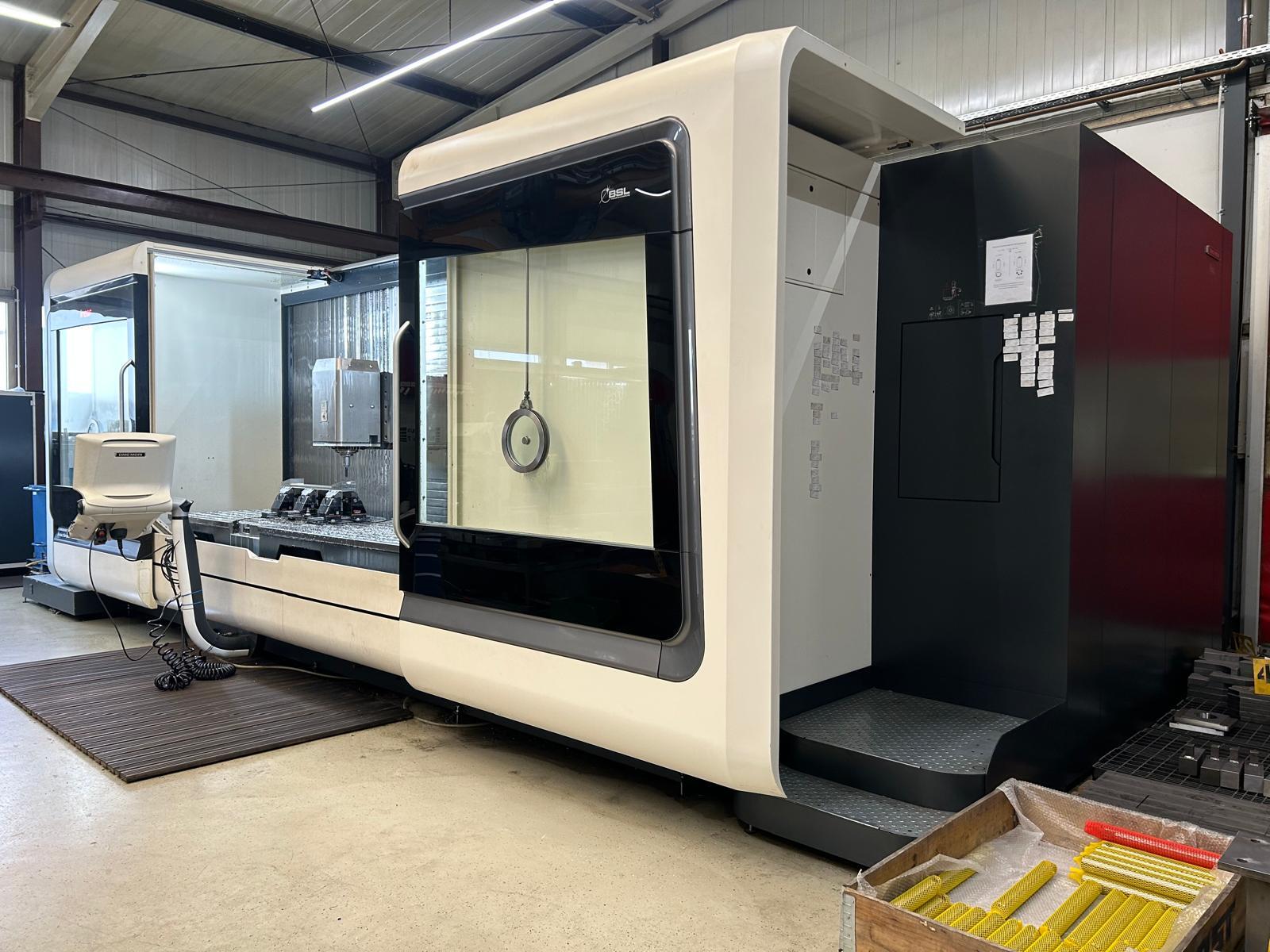

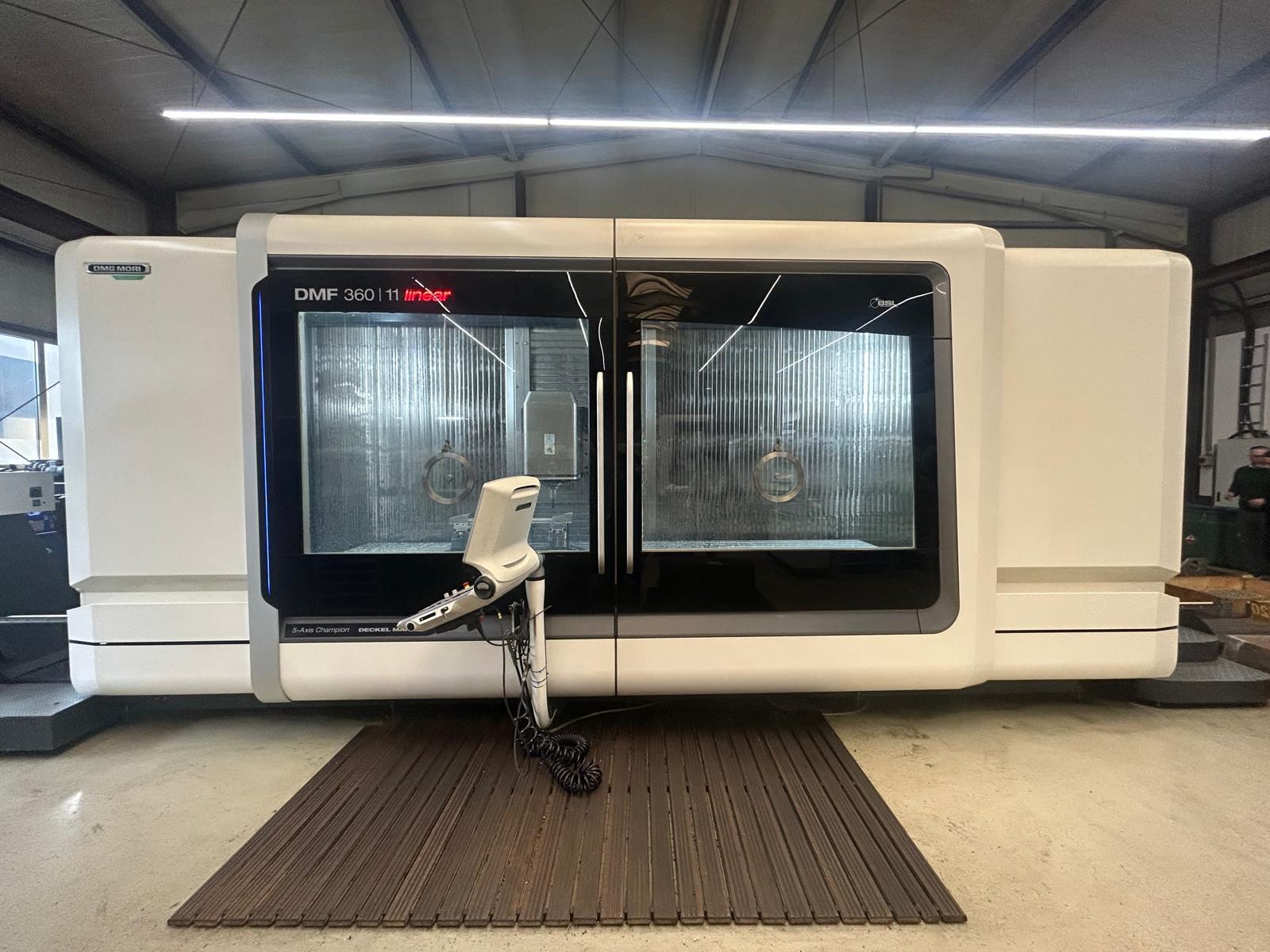

Used DMG DMF 360 / 11 linear

Universal machining center

DMG DMF 360 / 11 linear Milling machine used

| Universal machining center | |

| Machine type: | DMG DMF 360 / 11 linear |

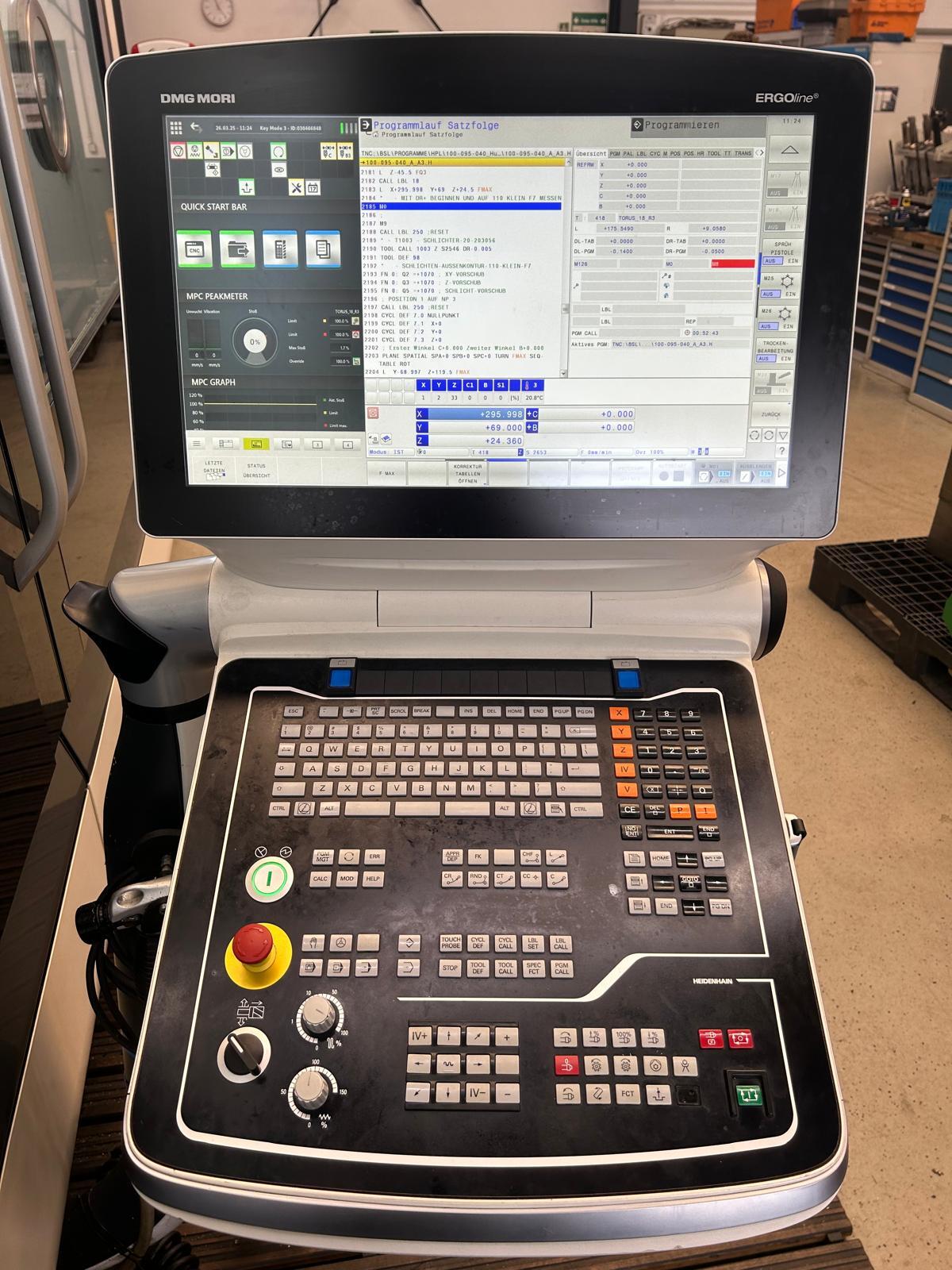

| Control: | Heidenhain TNC 640 Celos |

| Year: | 2022 |

| SPECIFICATIONS: | |

| Travel: | |

| X-Axis: [mm] | 3.600 |

| Y-Axis: [mm] | 1.100 |

| Z-Axis: [mm] | 900 |

| B-Axes | |

| C-Axis | |

| Amount of controlled axes: | 5 |

| Dynamikpaket für DMF 360 linear (Y1100) | |

| Rapid motion: (X/Y/Z) [m/min.] | 80 / 60 / 60 |

| Spindle speeds: [rpm] | 20 - 10.000 |

| Spindle power: [kW] | 44 / 32 |

| Torque: [Nm] | 288 / 187 |

| Tool: | SK 50 |

| Toolchanger | |

| Tool capacity: | 120 |

| NC rotary table | |

| Table size: [mm] | 4.200 x 1.100 |

| Max. Table Load: [kg] | 1.200 |

| Equipment: | |

| Internal cooling: [bar] | 40 |

| Cooling tank: [l] | 980 |

| Chip conveyor | |

| Chip rinsing pistol | |

| Oil mist separator | |

| Air blow | |

| Caliper | Heidenhain TS 460 |

| Vorbereitung für den Einsatz 3D quickSet | |

| Automatic doors | |

| Electronical handwheel | |

DMG DMF 360 / 11 linear Milling machine used

| Universal machining center | |

| Machine type: | DMG DMF 360 / 11 linear |

| Control: | Heidenhain TNC 640 Celos |

| Year: | 2022 |

| SPECIFICATIONS: | |

| Travel: | |

| X-Axis: [mm] | 3.600 |

| Y-Axis: [mm] | 1.100 |

| Z-Axis: [mm] | 900 |

| B-Axes | |

| C-Axis | |

| Amount of controlled axes: | 5 |

| Dynamikpaket für DMF 360 linear (Y1100) | |

| Rapid motion: (X/Y/Z) [m/min.] | 80 / 60 / 60 |

| Spindle speeds: [rpm] | 20 - 10.000 |

| Spindle power: [kW] | 44 / 32 |

| Torque: [Nm] | 288 / 187 |

| Tool: | SK 50 |

| Toolchanger | |

| Tool capacity: | 120 |

| NC rotary table | |

| Table size: [mm] | 4.200 x 1.100 |

| Max. Table Load: [kg] | 1.200 |

| Equipment: | |

| Internal cooling: [bar] | 40 |

| Cooling tank: [l] | 980 |

| Chip conveyor | |

| Chip rinsing pistol | |

| Oil mist separator | |

| Air blow | |

| Caliper | Heidenhain TS 460 |

| Vorbereitung für den Einsatz 3D quickSet | |

| Automatic doors | |

| Electronical handwheel | |

Request price for DMG DMF 360 / 11 linear:

DMG DMF 360 / 11 linear – High-Precision Milling Center for Demanding Applications

The DMG DMF 360 / 11 linear is a high-performance milling center designed specifically for complex manufacturing tasks in tooling, mold making, and mechanical engineering. Linear drives provide high dynamics and precision, allowing efficient machining of complex geometries and freeform surfaces.

Technical Data of the DMF 360 / 11 linear

The DMF 360 / 11 linear offers travels of approximately 360 mm in X, 360 mm in Y, and 360 mm in Z. The working area can accommodate workpieces up to 400 mm in diameter and 300 kg in weight. The spindle achieves up to 20,000 rpm with a power of around 18 kW, depending on the configuration. Tool clamping is via HSK-A63, supported by a chain magazine for up to 60 tools.

Control is via Heidenhain iTNC 640 or Siemens 840D / CELOS and enables precise machining with positioning accuracy of 4–5 µm. Optional features include internal coolant, probes, and chip conveyors for process reliability and repeatability.

Special Features & Advantages

Linear drives provide high dynamics while maintaining precision. The compact machine reduces floor space (approx. 7 m²) and allows easy access to the working area through large doors. The machine is robust, suitable for both prototypes and small to medium series. Automation solutions can be easily integrated.

Applications & Industries

The DMG DMF 360 / 11 linear is particularly suitable for:

- Tool and mold making – complex freeform surfaces, mechatronic molds

- Aerospace – precise components with tight tolerances

- Automotive – prototypes, series components, transmission parts

- Medical technology – implants, instruments with high surface quality

- Mechanical engineering – precise components, housings, assemblies

Buying a Used DMF 360 / 11 linear – An Economic Option

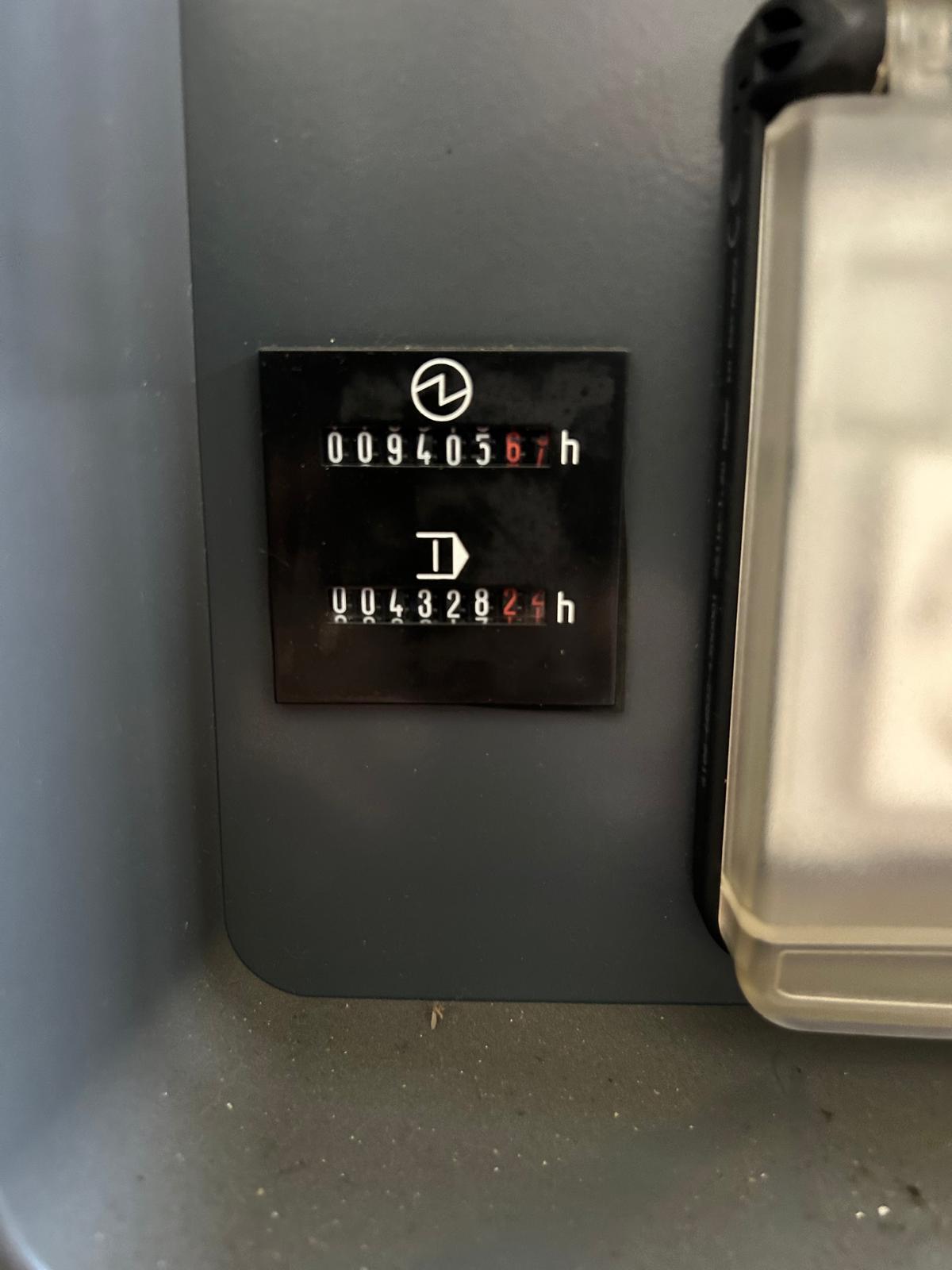

Those looking to reduce investment costs can consider used DMF 360 / 11 linear machines. Well-maintained units with service history and documented operating hours are often available.

When purchasing, check spindle hours, tool changer condition, and control version. A reliable dealer and optional service contract can make a used machine a very economical alternative.

Alternatives to the DMF 360 / 11 linear

Alternatives can be found within the DMG MORI portfolio and from other manufacturers:

- Okuma MU-Series – robust machines with advanced thermal compensation, ideal for heavy workpieces

- Mazak Variaxis / Integrex – flexible 5-axis and multitasking machines

- GROB 5-Axis Centers – stable and precise, widely used in automotive and aerospace

- Hermle C-Series – proven precision machines for tool and mold making

The choice of machine depends on individual requirements for footprint, precision, automation, and investment budget.