SOLD: Degen UTB800-G Deep hole drilling machine

CNC Deephole Drilling Center

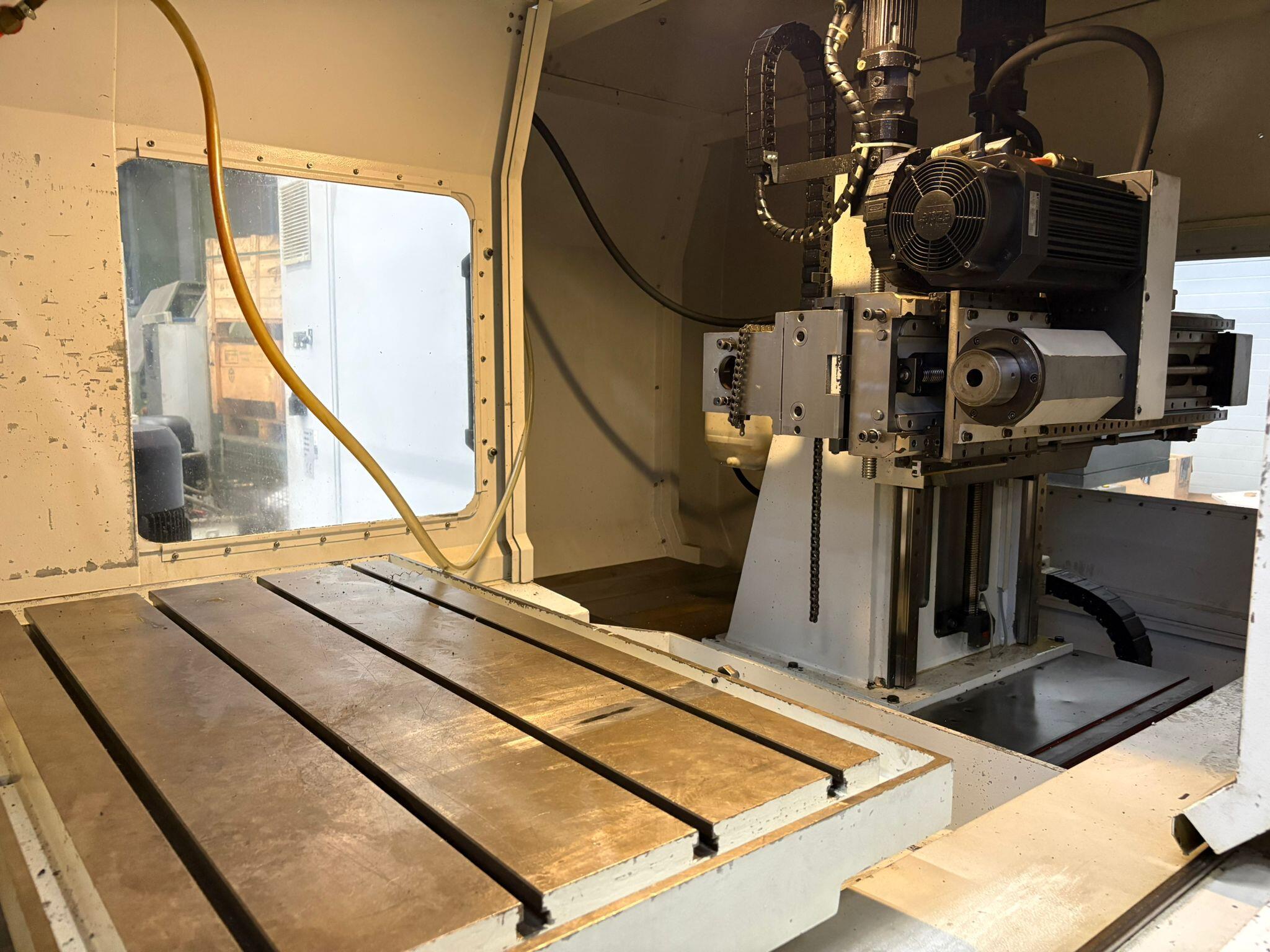

Used CNC Deephole Drilling Center Degen UTB800-G

| CNC Deephole Drilling Center | |

| Machine type: | Degen UTB800/G |

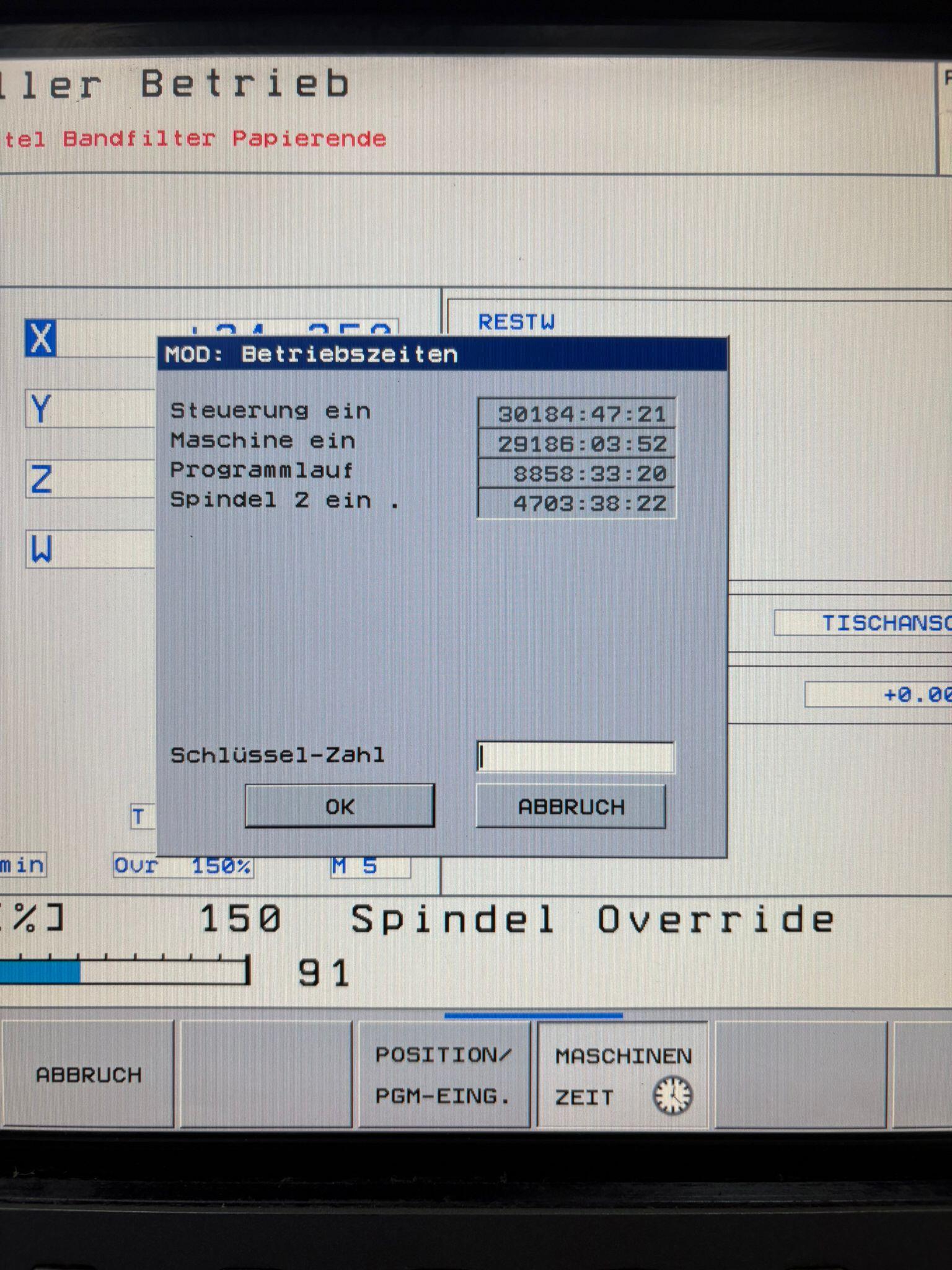

| Control: | Heidenhain TNC 320 |

| Year: | 2008 |

| SPECIFICATIONS: | |

| Travel: | |

| X-Axis: [mm] | 630 |

| Y-Axis: [mm] | 400 |

| Z-Axis: [mm] | 800 |

| W-axes: [mm] | 600 |

| feed rate [mm/min] | 6.000 |

| Angular range: | Z: +/- 10° |

| Table size: [mm] | 1.100 x 650 |

| Max. Table Load: [kg] | 2.000 |

| Tisch manuel drehbar | |

| Tool: | MK3 |

| Max. revolution: [rpm] | 4.000 |

| Spindle power: [kW] | 7,5 / 5,5 |

| Bohrdurchmesser: 4-25 mm | |

| Accessories: | |

| High pressure pumps | |

| Internal cooling: [bar] | 0-90 |

| Cooling tank: [l] | 600 |

| paper band filter | |

Used CNC Deephole Drilling Center Degen UTB800-G

| CNC Deephole Drilling Center | |

| Machine type: | Degen UTB800/G |

| Control: | Heidenhain TNC 320 |

| Year: | 2008 |

| SPECIFICATIONS: | |

| Travel: | |

| X-Axis: [mm] | 630 |

| Y-Axis: [mm] | 400 |

| Z-Axis: [mm] | 800 |

| W-axes: [mm] | 600 |

| feed rate [mm/min] | 6.000 |

| Angular range: | Z: +/- 10° |

| Table size: [mm] | 1.100 x 650 |

| Max. Table Load: [kg] | 2.000 |

| Tisch manuel drehbar | |

| Tool: | MK3 |

| Max. revolution: [rpm] | 4.000 |

| Spindle power: [kW] | 7,5 / 5,5 |

| Bohrdurchmesser: 4-25 mm | |

| Accessories: | |

| High pressure pumps | |

| Internal cooling: [bar] | 0-90 |

| Cooling tank: [l] | 600 |

| paper band filter | |

Degen UTB800-G – High-Precision Deep Hole Drilling Center

Degen UTB800-G is a powerful deep hole drilling center designed for high-precision machining of holes with large length-to-diameter ratios. The machine stands out for its stability, accuracy, and reliability, making it ideal for demanding industrial applications.

Technical Specifications and Equipment of the Degen UTB800-G

The Degen UTB800-G features a highly rigid construction that minimizes vibrations and ensures precise drilling results. With a drilling capacity of up to 800 mm in depth and the ability to machine various diameters, the machine is suitable for a wide range of materials. Its precise feed system and powerful spindle drive ensure consistent machining quality. Integrated cooling systems and monitoring devices provide process reliability and long tool life.

Key Features and Advantages

The machine is distinguished by robust guide systems, high rigidity, and precise spindle technology. This ensures consistently high drilling quality even at great depths. The design emphasizes ease of operation and maintenance, minimizing downtime.

Manufacturer Degen – Quality from Experience

Degen is a renowned manufacturer of deep hole drilling centers and special machines with decades of experience in mechanical engineering. The company focuses on precision, reliability, and innovative technologies. Degen machines are known for their longevity, thoughtful design, and excellent build quality, making them a preferred choice for industrial companies worldwide.

What is a Deep Hole Drilling Center and Its Applications?

A deep hole drilling center is a specialized machine for drilling very deep holes with strict requirements for straightness, roundness, and surface quality. Typical applications include hydraulic components, cylinders, valves, tool and mold making, as well as machinery and plant construction. Deep hole drilling centers enable holes that cannot be economically or precisely achieved with standard drilling machines or machining centers.

Service and Maintenance

Regular maintenance is essential for the reliable and long-term operation of the Degen UTB800-G. Information about our service offerings can be found on our service page.