SOLD: Milling machine Kern Micro

Storage

Used CNC machining center Kern Micro

| Ultrapräzisions-CNC-Bearbeitungszentrum | |

| Machine type: | Kern Micro |

| Control: | Heidenhain TNC640 |

| Year: | 2017 |

| SPECIFICATIONS: | |

| X-Axis: [mm] | 350 |

| Y-Axis: [mm] | 220 |

| Z-Axis: [mm] | 250 |

| Feed: (X/Y/Z) [m/min.] | 30 |

| Beschleunigung 10 m/s2 | |

| Spindle speeds: [rpm] | 500 - 42.000 |

| Torque: [Nm] | 6 bei 24.000 1/min, 3,4 bei 42.000 1/min. |

| Spindle motor: [kW] | 15 / 20 |

| Tool: | HSK-E40 |

| Tool capacity: | 186 |

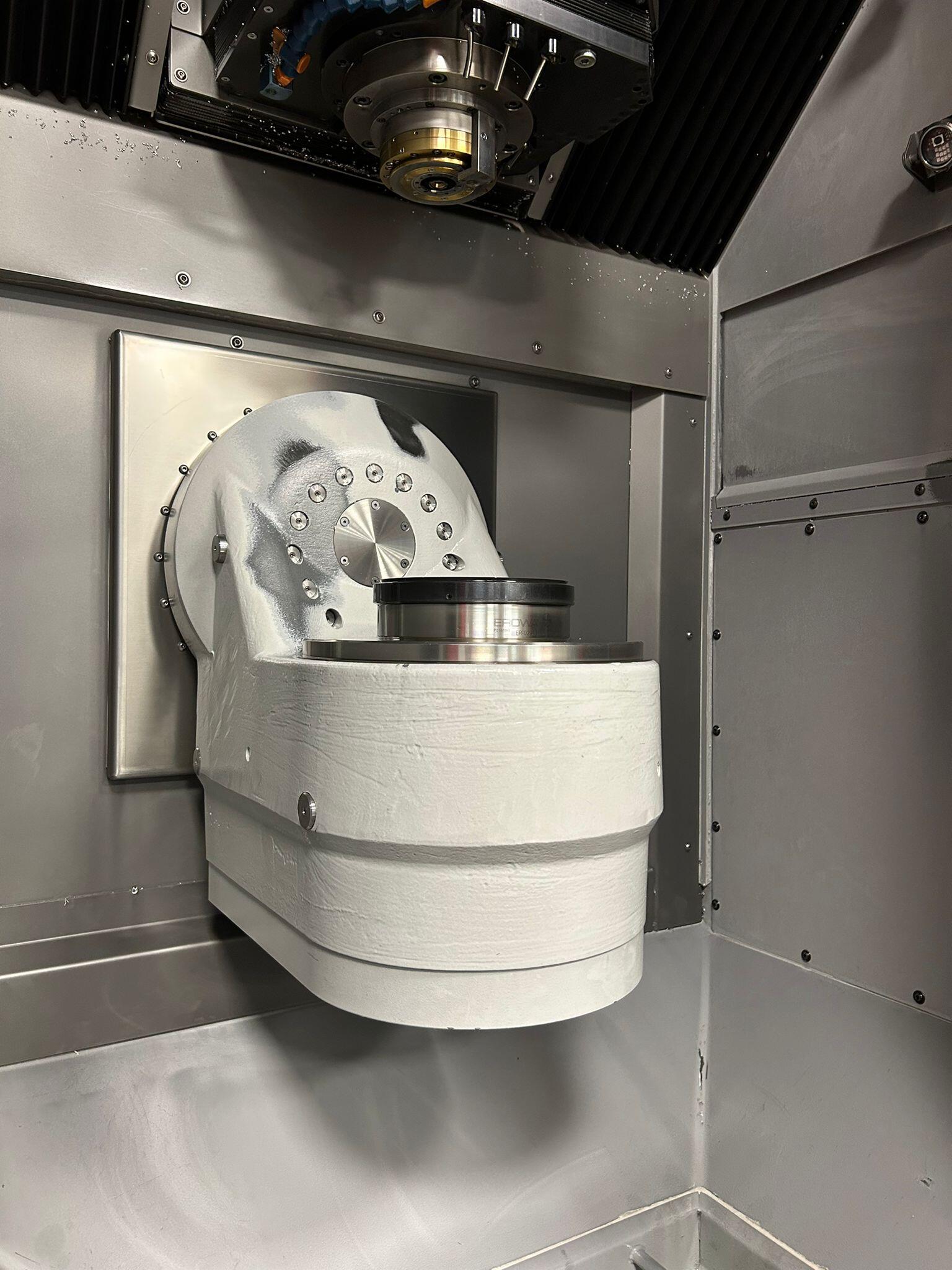

| NC-panning and rotary Table | |

| Angular range: | -110° - +110° |

| Schwenkgeschwindigkeit: 600°/s | |

| Drehgeschwindigkeit: 200 1 /min | |

| Haltemoment Schwenkachse geklemmt: 300 Nm | |

| Equipment: | |

| Internal cooling: [bar] | 80 |

| Caliper | BLUM TC52 LF |

| Tool breakage detector | Blum Nano NT (BL 103) |

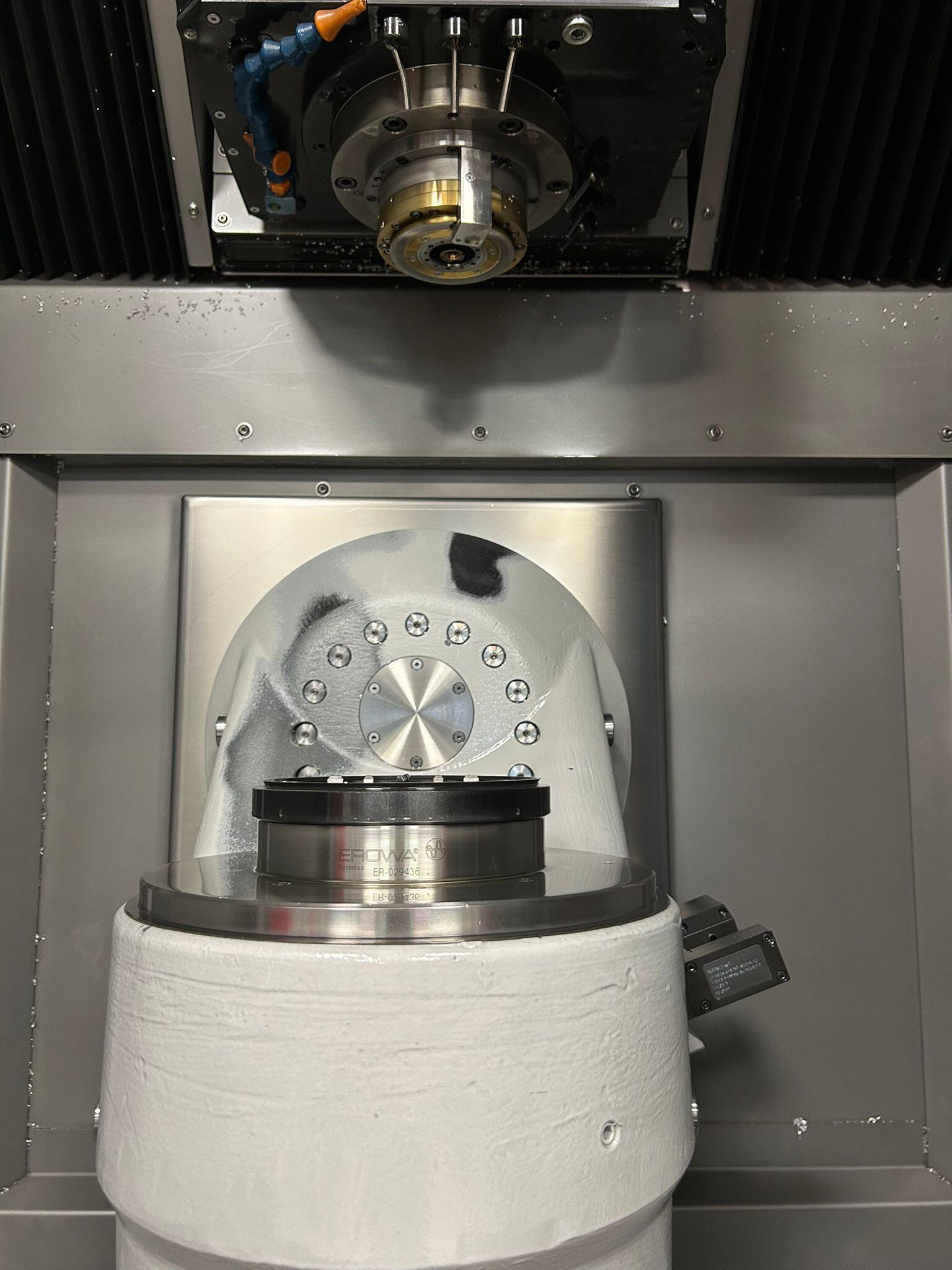

| Erowa Power Chuck P für Ausbau 5-achsig | |

| Erowa Robot Easy (ERE) ITS148 | |

| paper band filter | |

| Chip rinsing pistol | |

| Fire-extinguishing system | CO2 |

Used CNC machining center Kern Micro

| Ultrapräzisions-CNC-Bearbeitungszentrum | |

| Machine type: | Kern Micro |

| Control: | Heidenhain TNC640 |

| Year: | 2017 |

| SPECIFICATIONS: | |

| X-Axis: [mm] | 350 |

| Y-Axis: [mm] | 220 |

| Z-Axis: [mm] | 250 |

| Feed: (X/Y/Z) [m/min.] | 30 |

| Beschleunigung 10 m/s2 | |

| Spindle speeds: [rpm] | 500 - 42.000 |

| Torque: [Nm] | 6 bei 24.000 1/min, 3,4 bei 42.000 1/min. |

| Spindle motor: [kW] | 15 / 20 |

| Tool: | HSK-E40 |

| Tool capacity: | 186 |

| NC-panning and rotary Table | |

| Angular range: | -110° - +110° |

| Schwenkgeschwindigkeit: 600°/s | |

| Drehgeschwindigkeit: 200 1 /min | |

| Haltemoment Schwenkachse geklemmt: 300 Nm | |

| Equipment: | |

| Internal cooling: [bar] | 80 |

| Caliper | BLUM TC52 LF |

| Tool breakage detector | Blum Nano NT (BL 103) |

| Erowa Power Chuck P für Ausbau 5-achsig | |

| Erowa Robot Easy (ERE) ITS148 | |

| paper band filter | |

| Chip rinsing pistol | |

| Fire-extinguishing system | CO2 |

Kern Micro – Precision Machining Center for Demanding Applications

The Kern Micro is a high-precision machining center designed specifically for manufacturing small, complex components. The machine impresses with its high stability, excellent repeatability, and compact design. It is ideal for industries where the tightest tolerances and surface quality are critical.

Key Technical Data at a Glance

The Kern Micro offers travels of approximately 200 mm in X, 150 mm in Y, and 100 mm in Z. Workpieces up to 100 mm in diameter and 5 kg in weight can be processed without difficulty. The core is the high-frequency spindle system, which achieves speeds up to 100,000 rpm with around 5 kW power. Tool clamping is via HSK-E25, usually combined with a magazine system for up to 20 tools.

Control is provided by proven systems such as Heidenhain iTNC 530 or Siemens 840D / CELOS. With positioning accuracy in the 1–2 µm range, the Kern Micro meets the highest requirements for precision and process reliability.

Main Features & Highlights

The machine stands out for its compact design and thermal stability. Highly precise ball screws and linear guides ensure excellent dynamics and repeatability. A particular highlight is Kern's patented micro-gap hydrostatics: the integral design combined with linear motors makes the machine more robust and consumes around 80% less energy than conventional hydrostatic systems. The minimal gap also increases stiffness and damping, resulting in superior surface finish and accuracy. With a footprint of only about 4 m², the Kern Micro integrates easily into existing production environments. Optional features include internal cooling, touch probes, and automation solutions.

Typical Applications and Industries

The Kern Micro is especially suitable for:

- Medical technology – implants, surgical instruments requiring highest precision

- Watchmaking and jewelry – micro-components and delicate parts

- Electronics – small housings, precision contacts, PCB components

- Aerospace – micro-parts with extremely tight tolerances

- Precision mechanics – sensors, instruments, and small assemblies

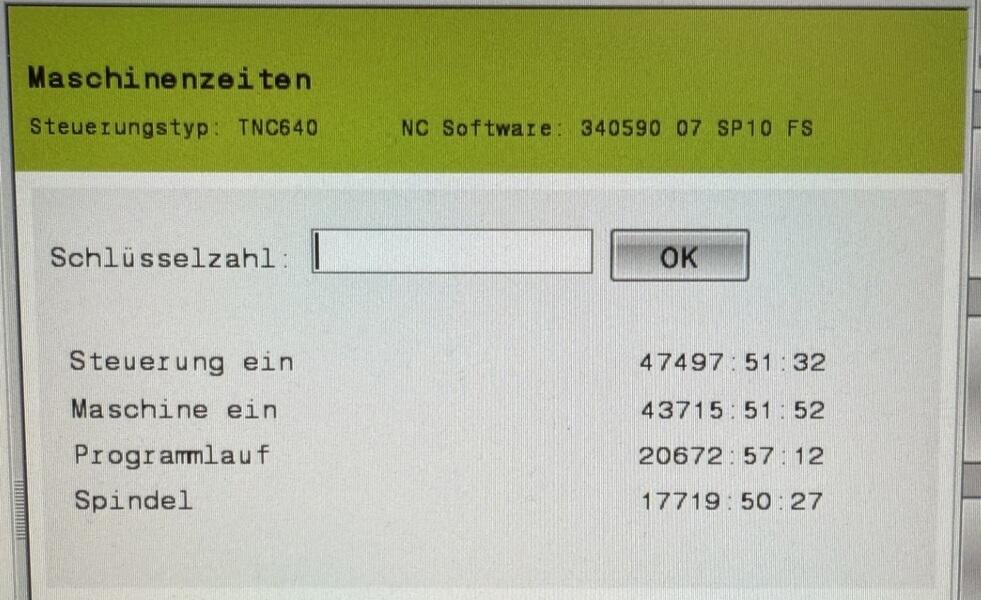

Buying a Used Kern Micro – Cost-Effective Option

For companies looking to reduce investment costs, the market for used Kern Micro machines is an attractive option. Well-maintained machines with documented operating hours are often available.

When purchasing, attention should be paid to the condition of the high-frequency spindle, the tool changer, and the control version. A reliable dealer and an optional service contract can significantly increase the economic value of a used machine.

Alternative Machine Solutions

Alternatives can be found both in other manufacturers’ portfolios and among similar high-precision machining centers:

- Okuma MU-Series – compact, robust machines with high repeatability

- Mazak Variaxis / Integrex – flexible 5-axis and multitasking solutions

- GROB 5-axis precision centers – stable and precise, also suitable for small parts

- Hermle C-Series – proven precision machines for micro-components