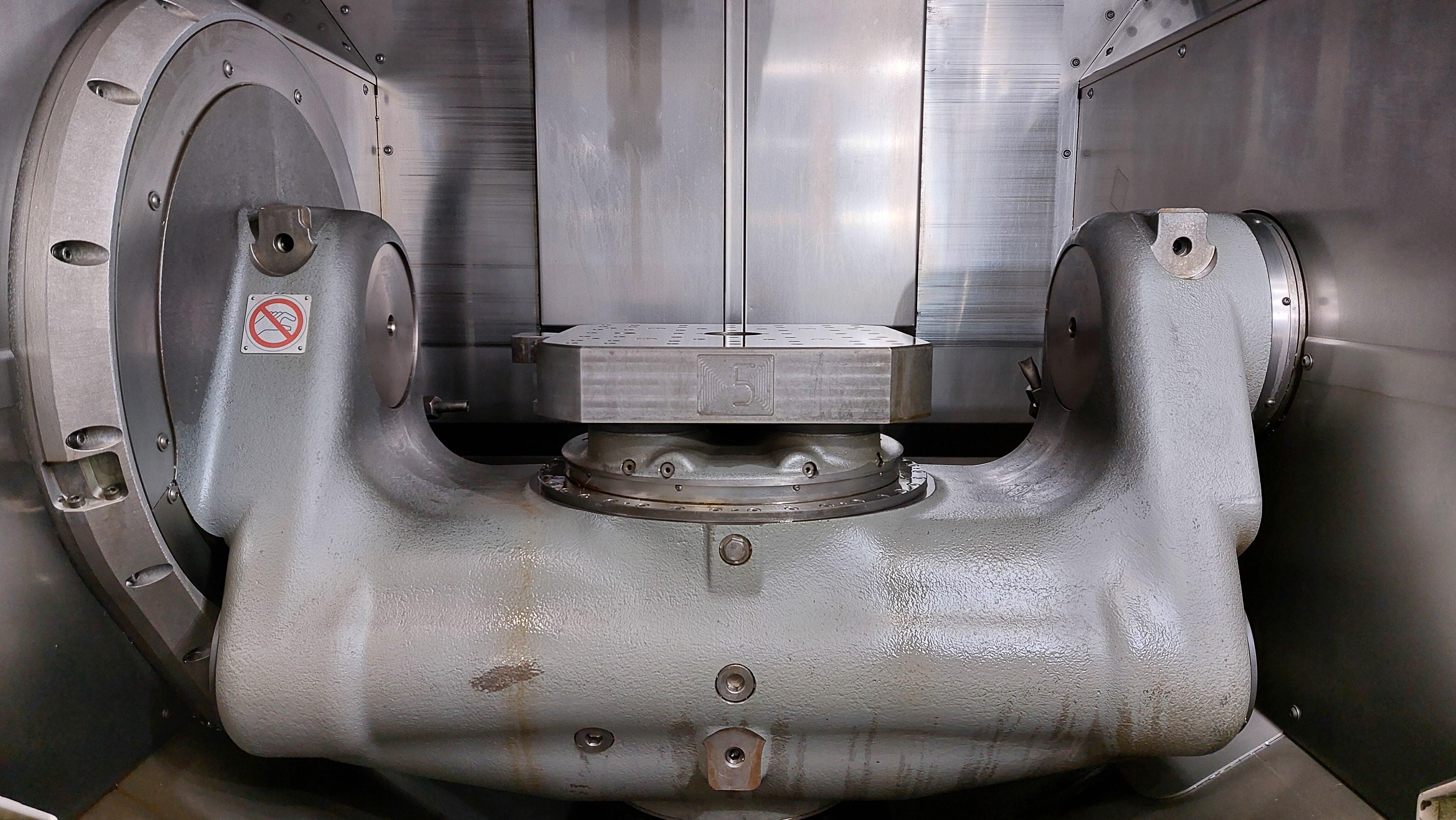

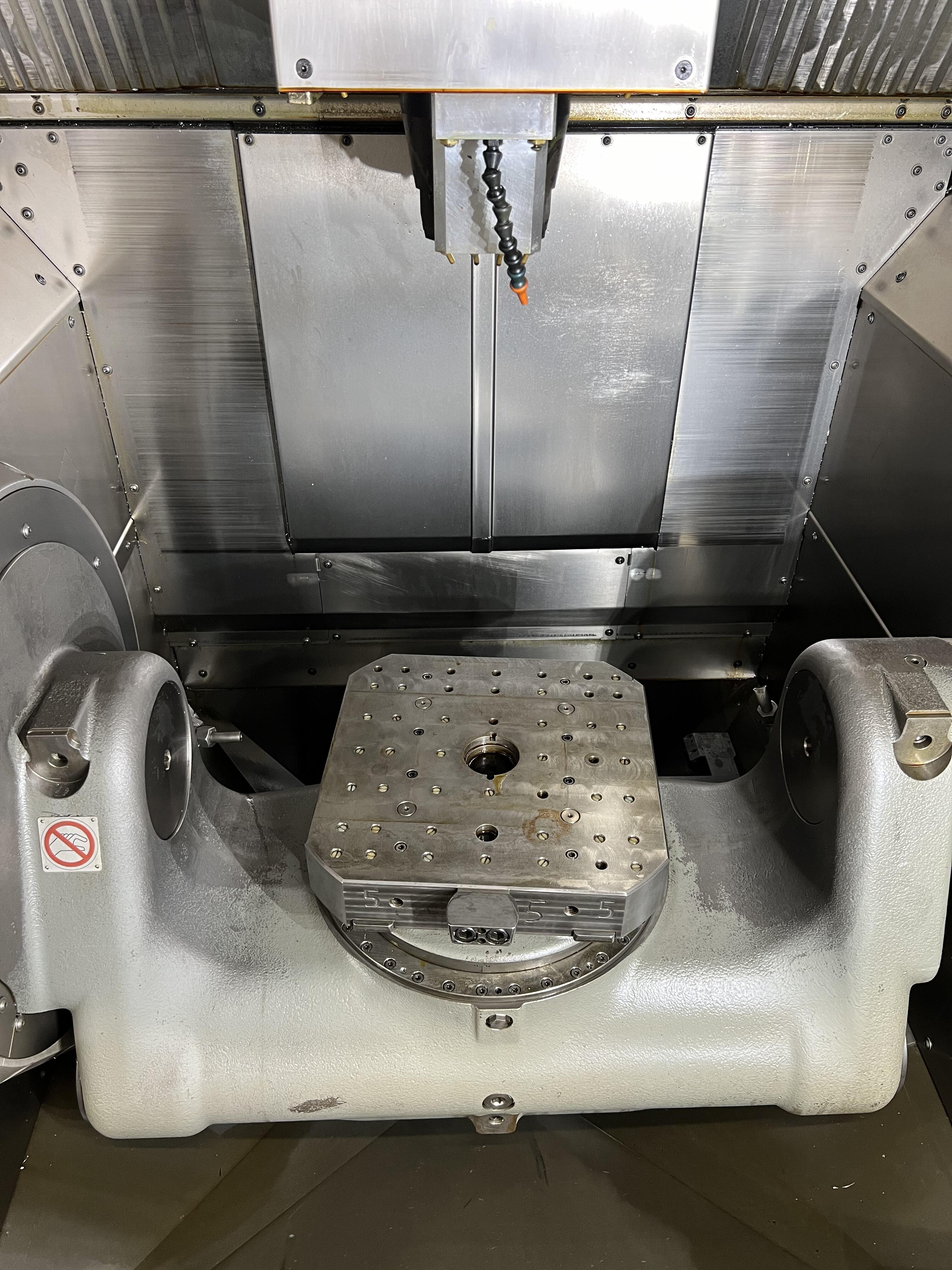

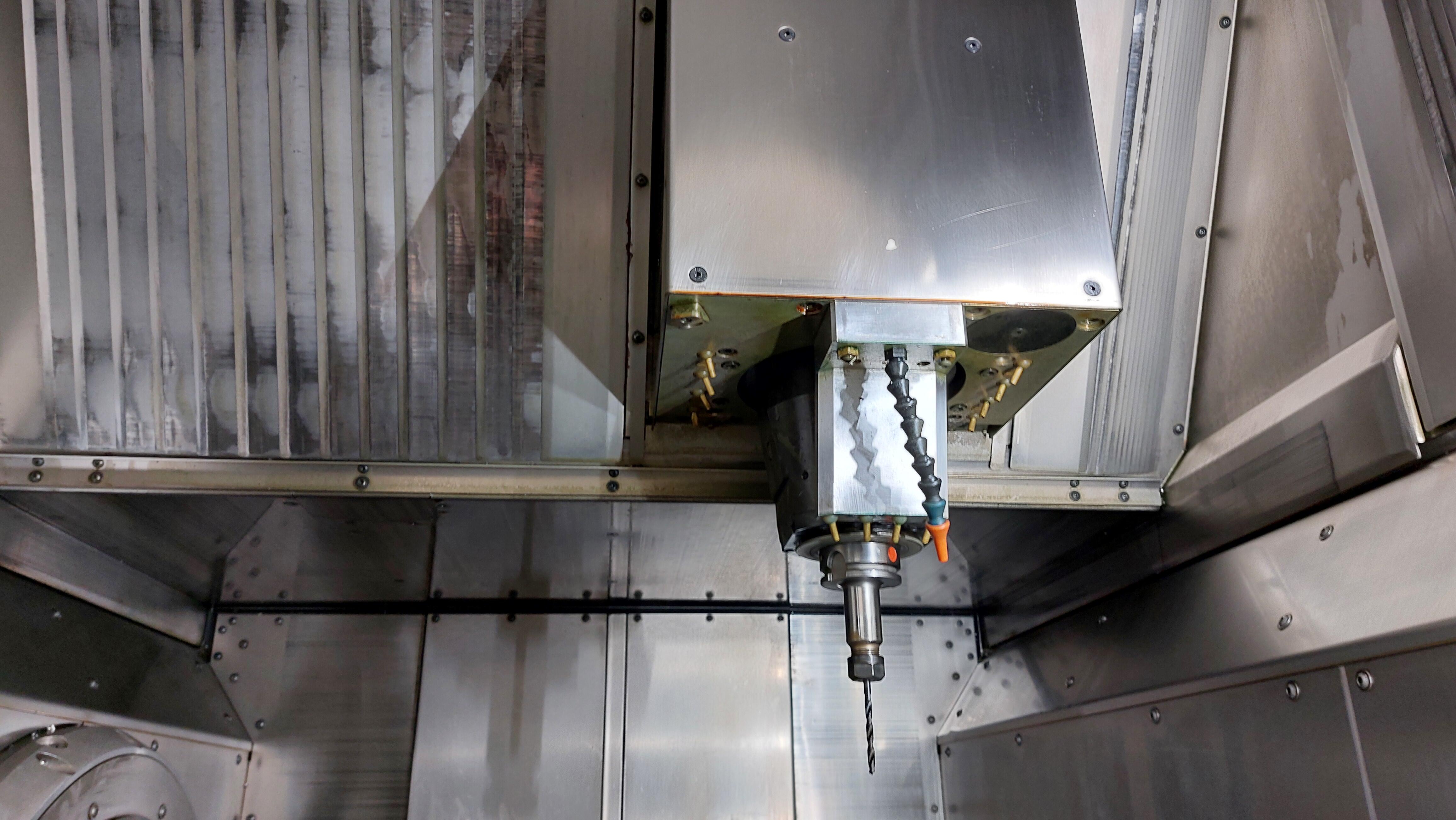

Hermle C 22 UP – Flexible 5-Axis Universal Machining Center

The Hermle C 22 UP is a high-precision universal machining center, specially designed for complex workpieces. Its compact design and stable machine construction make it ideal for tool and mold making as well as for high-precision series production.

Technical specifications and features of the Hermle C 22 UP

The Hermle C 22 UP offers generous travel ranges of approximately 550 mm in X, 450 mm in Y, and 450 mm in Z, allowing for easy machining of medium-sized workpieces. The machine features a powerful spindle unit capable of speeds up to 24,000 rpm. A highlight is the integrated 8-pallet changer, which enables efficient and flexible production of multiple workpieces without long setup times. Tool holding is via HSK-A63, and the tool magazine accommodates up to 60 tools.

Key features and advantages

The Hermle C 22 UP excels in rigidity and precision thanks to its one-piece cast machine bed and robust guideways. The compact footprint of approx. 7 m² combined with the large work area opening ensures easy accessibility. With precise control, optional internal cooling, touch probes, and automatable features, high process reliability is ensured.

Applications and typical industries

- Tool and mold making – complex freeform surfaces and mechatronic molds.

- Aerospace – precision components, tight tolerances, challenging materials.

- Automotive – prototypes, series components, housings and parts.

- Medical technology – implants and instruments, highest surface quality required.

- Mechanical engineering – housings, distributors, and other complex components.

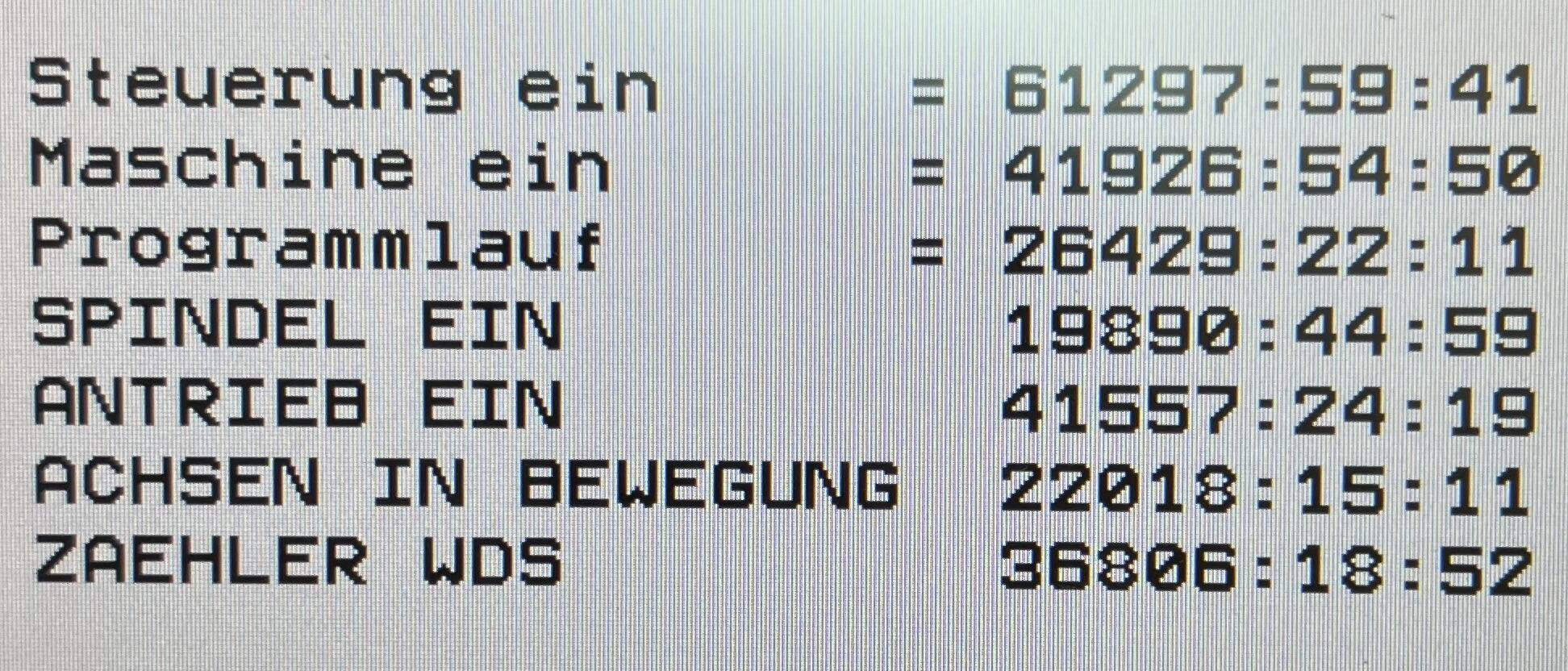

Hermle C 22 UP – Maintenance and service

Regular maintenance is essential for reliable and long-lasting operation of the Hermle C 22 UP. More information and service options are available on our service page.

Alternative 5-axis machining centers

Alternatives to the Hermle C 22 UP include other 5-axis machining centers depending on workpiece size, automation, and investment requirements: