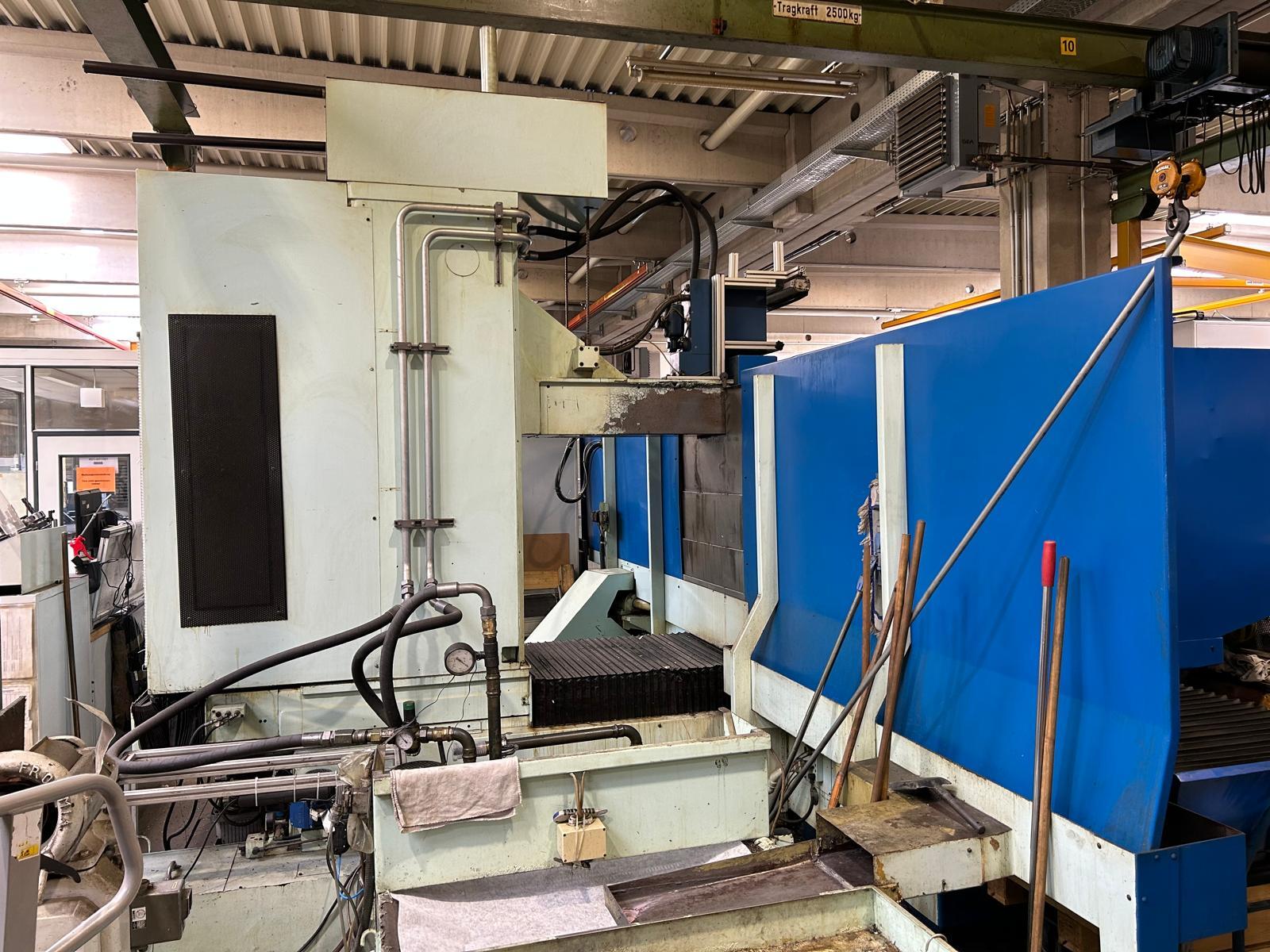

Elb Schliff SWDE 012 NPC-K Grinding machine used

CNC Surface Grinding Machine

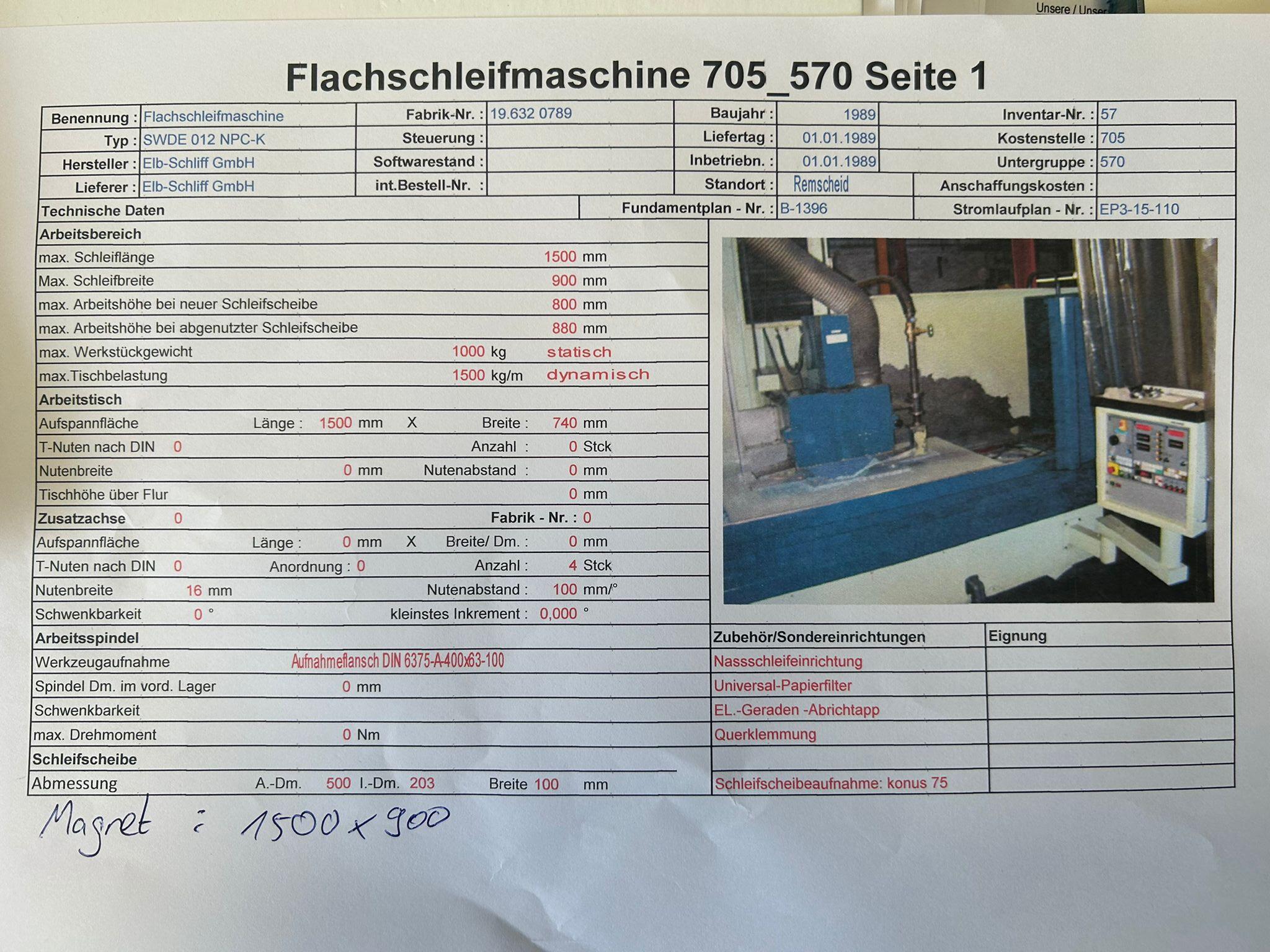

Elb Schliff SWDE 012 NPC-K - used CNC surface grinding machine

| CNC Surface Grinding Machine | |

| Machine type: | Elb Schliff SWDE 012 NPC-K |

| Year: | 1989 |

| SPECIFICATIONS: | |

| max. grinding length [mm] | 1.500 |

| max. grinding width [mm] | 900 |

| max. Arbeitshöhe mit neuer Schleifscheibe: 800 mm | |

| max. Arbeitshöhe bei abgenutzter Scheibe: 880 mm | |

| Max. workpiece weight: [kg] | 1.000 kg statisch |

| Max. Table Load: [kg] | 1.500 kg/m dynamisch |

| grinding wheel-Ø [mm] | 500 |

| Grinding wheel width [mm]: | 100 |

| Table size: [mm] | 1.500 x 740 |

| Equipment: | |

| paper band filter | |

| Nassschleifeinrichtung | |

| EL.-Geraden-Abrichtapp | |

| Querklemmung | |

| grinding spindle taper | Konus 75 |

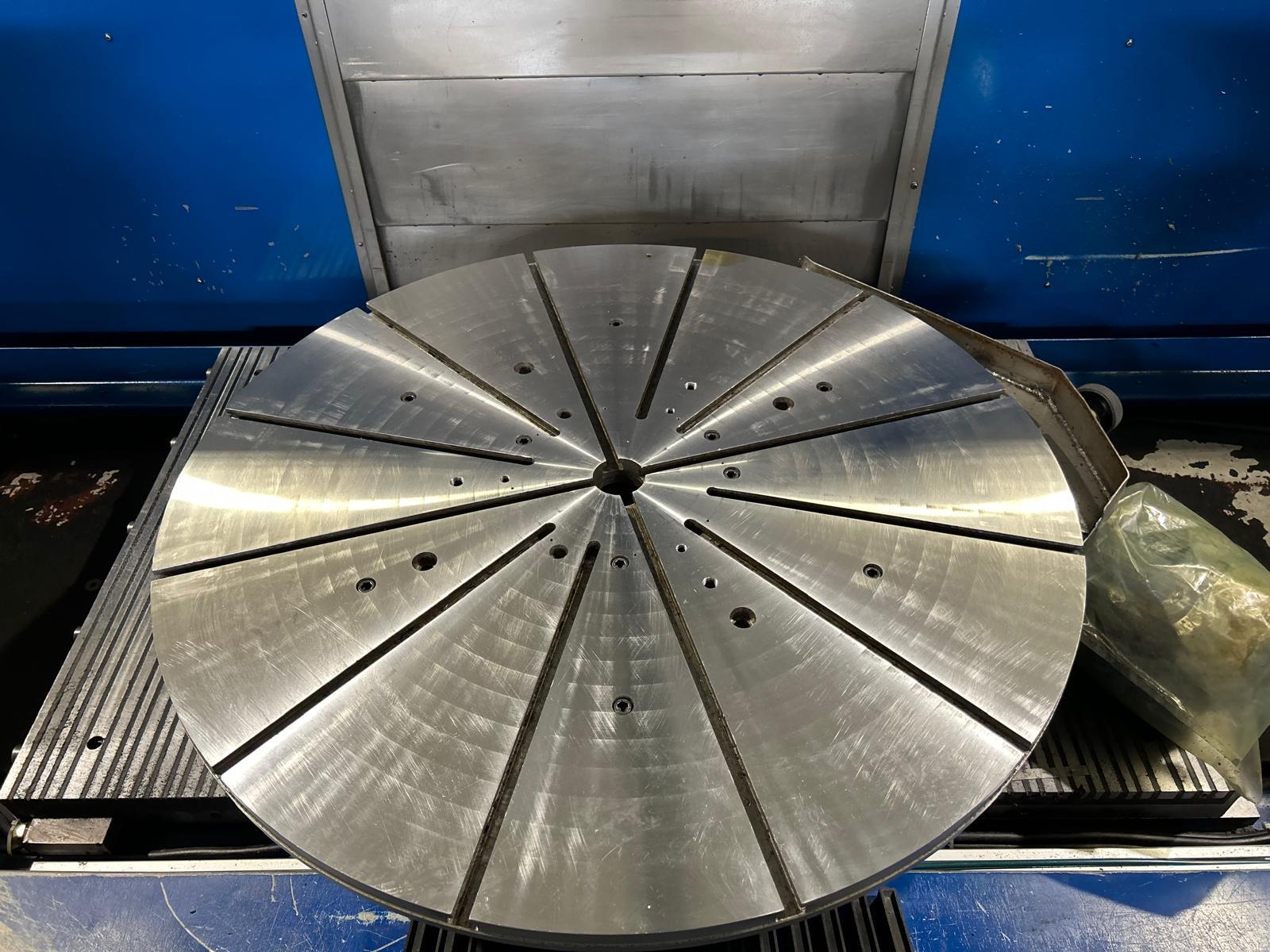

| magnetic plate | 1.500 x 900 |

| kein Rundtisch | |

Elb Schliff SWDE 012 NPC-K - used CNC surface grinding machine

| CNC Surface Grinding Machine | |

| Machine type: | Elb Schliff SWDE 012 NPC-K |

| Year: | 1989 |

| SPECIFICATIONS: | |

| max. grinding length [mm] | 1.500 |

| max. grinding width [mm] | 900 |

| max. Arbeitshöhe mit neuer Schleifscheibe: 800 mm | |

| max. Arbeitshöhe bei abgenutzter Scheibe: 880 mm | |

| Max. workpiece weight: [kg] | 1.000 kg statisch |

| Max. Table Load: [kg] | 1.500 kg/m dynamisch |

| grinding wheel-Ø [mm] | 500 |

| Grinding wheel width [mm]: | 100 |

| Table size: [mm] | 1.500 x 740 |

| Equipment: | |

| paper band filter | |

| Nassschleifeinrichtung | |

| EL.-Geraden-Abrichtapp | |

| Querklemmung | |

| grinding spindle taper | Konus 75 |

| magnetic plate | 1.500 x 900 |

| kein Rundtisch | |

Request price for Elb Schliff SWDE 012 NPC-K:

Elb Schliff SWDE 012 NPC-K – Precise CNC Surface Grinding Machine

Elb Schliff SWDE 012 NPC-K is a high-performance CNC surface grinding machine designed for maximum precision in flat workpiece surfaces. The machine stands out for its accuracy, stability, and reliability, making it ideal for serial production and complex grinding tasks in industry and toolmaking.

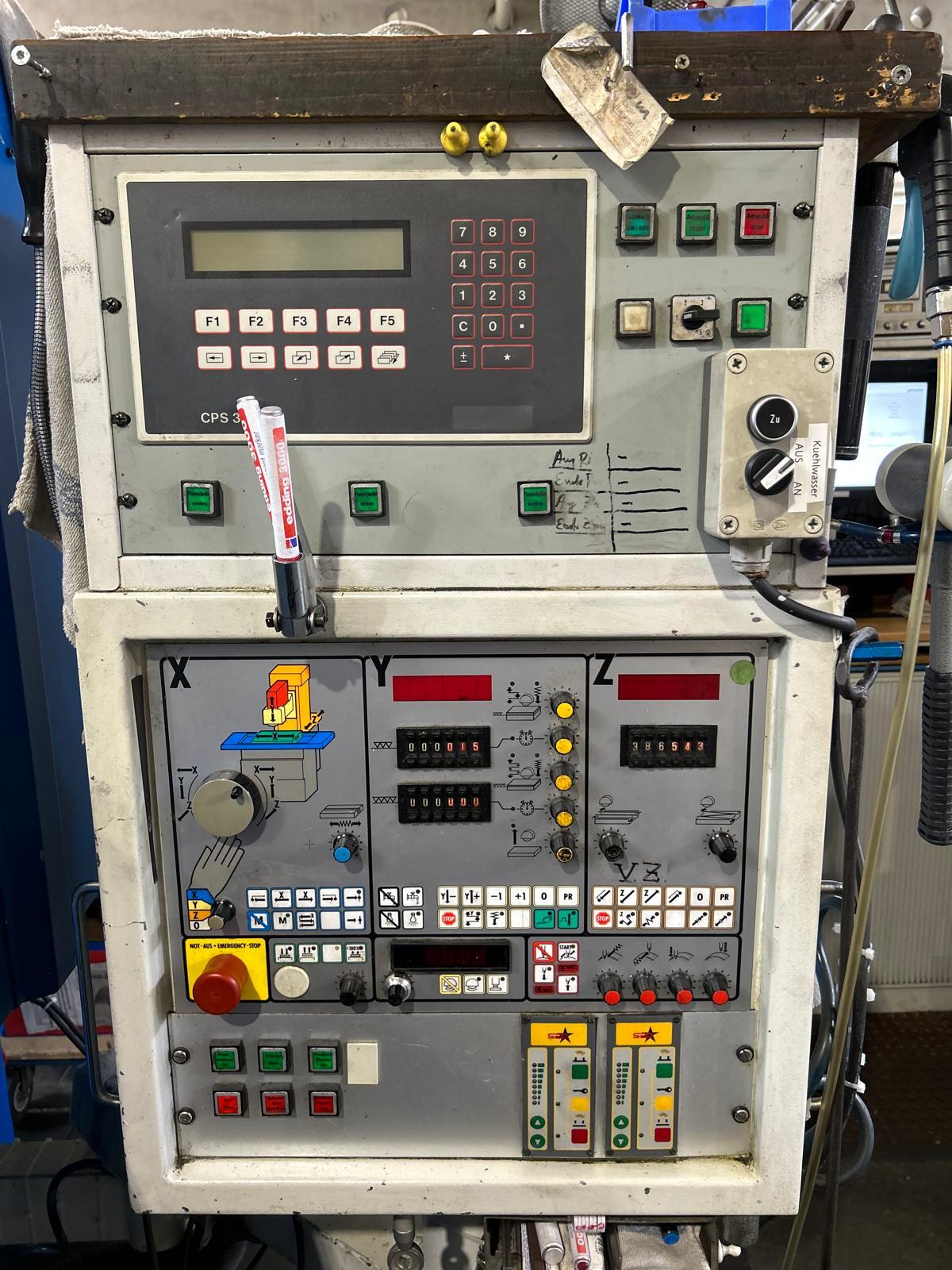

Technical Specifications and Features of the Elb Schliff SWDE 012 NPC-K

The SWDE 012 NPC-K offers generous grinding travel ranges, a stable machine bed structure, and highly precise guidance systems that minimize thermal deformation. The CNC control system allows complex grinding cycles and precise repeatability. High-quality grinding wheels, automatic wheel changes, and optional coolant supply ensure consistently high surface quality and efficiency. Its robust design also allows safe clamping and machining of heavy workpieces.

What is a CNC Surface Grinding Machine?

A CNC surface grinding machine is used to process flat surfaces of workpieces with high precision. It is particularly suitable for the finishing of metal and plastic parts where tolerances in the micrometer range are required. Typical applications include grinding of tool plates, guideways, pattern plates, or components for machine and plant engineering. CNC control allows complex grinding cycles to be automated and reproducible, significantly improving productivity and precision.

Key Features & Benefits

The Elb Schliff SWDE 012 NPC-K impresses with a stable machine structure, precise linear guides, high-quality spindles, and a modern CNC control system. Optional features include automatic workpiece clamping, wheel changers, and measuring systems. This ensures high process reliability, shorter setup times, and consistently high surface quality.

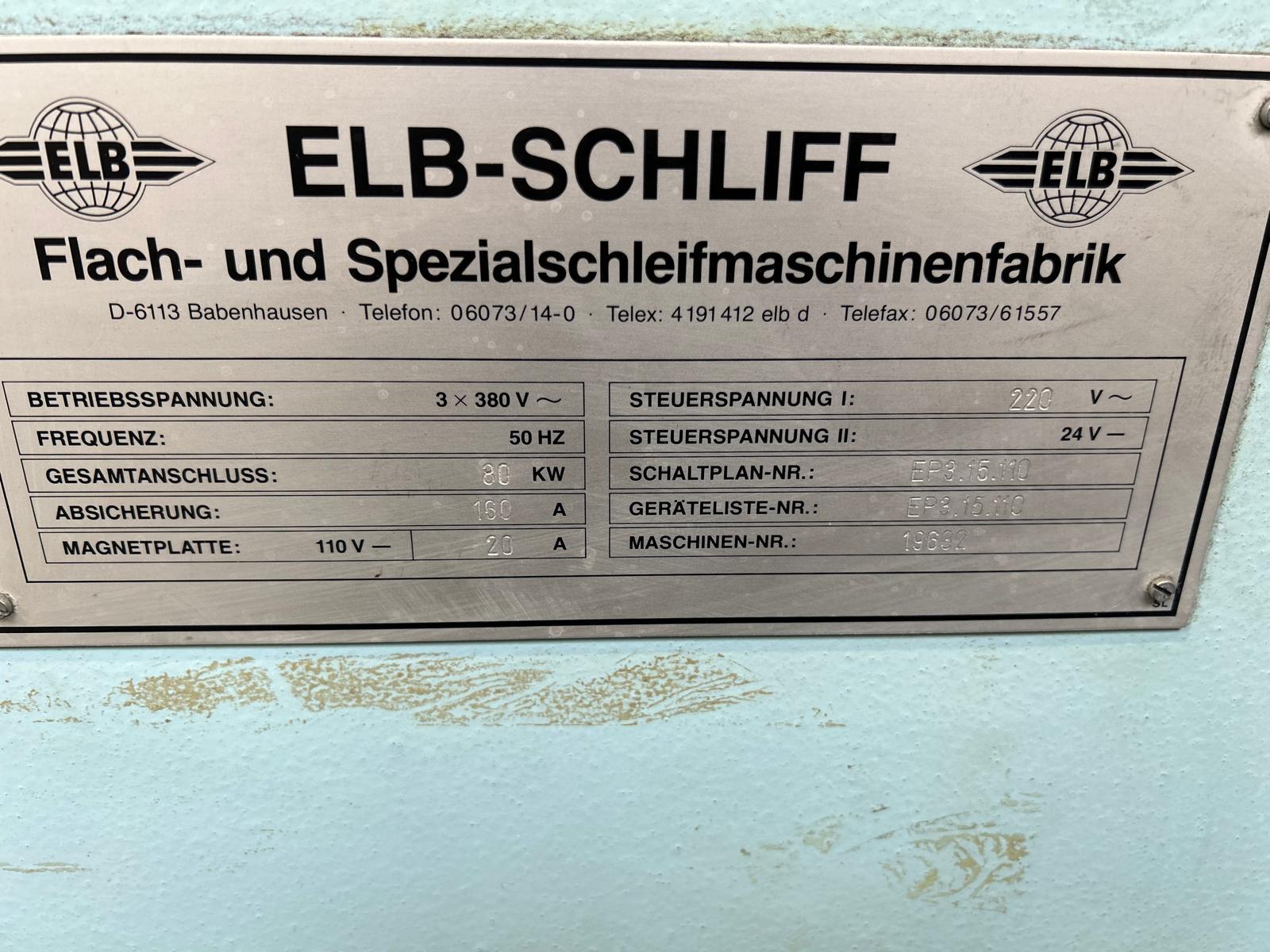

Manufacturer Elb Schliff – Precision from Germany

Elb Schliff is a German manufacturer of grinding machines with long-standing experience in precision machine construction. Elb Schliff machines are known for their high quality, durability, and technological innovation. With a focus on customer-specific solutions and high manufacturing standards, Elb Schliff is a reliable partner for companies that require maximum accuracy and surface quality.

Applications

The SWDE 012 NPC-K is used in various industries, including mechanical engineering, toolmaking, mold making, aerospace, and precision manufacturing. Typical workpieces include guide rails, tool plates, precision parts, and components where flat surfaces and tight tolerances are critical.

Service & Maintenance

Regular maintenance is essential for the long-term precision and reliability of the Elb Schliff SWDE 012 NPC-K. Information about our service offerings is available on our service page.