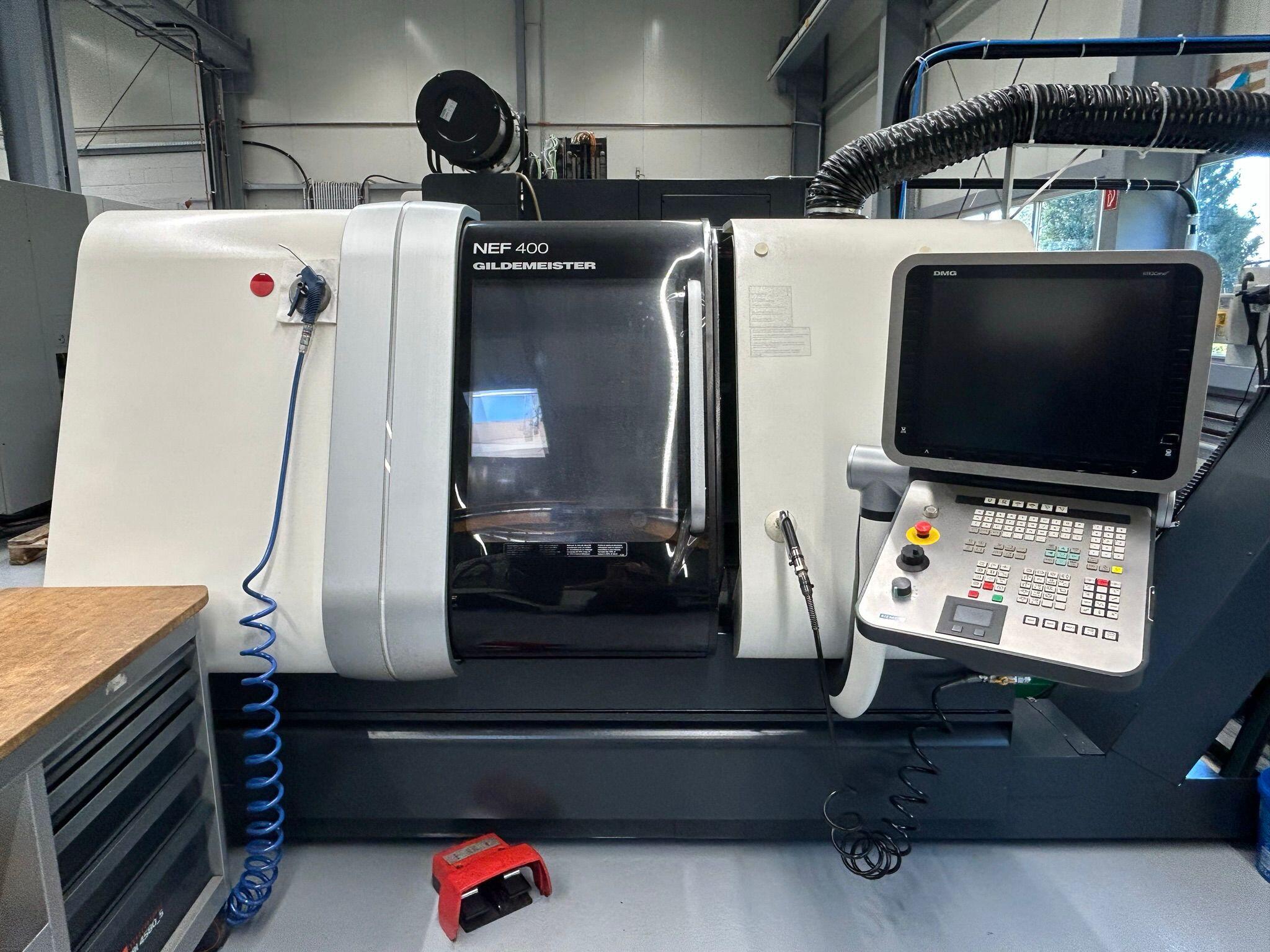

SOLD: Lathe machine DMG NEF 400

CNC - lathe machine

Used CNC lathe DMG NEF 400

| CNC - lathe machine | |

| Machine type: | DMG NEF 400 V1 |

| Control: | Siemens 840 D ShopTurn |

| Year: | 2012 |

| SPECIFICATIONS: | |

| Between centers: [mm] | 805 |

| Max. turning length: [mm] | 650 |

| Turningdiameter: [mm] | 350 |

| Max. swing over bed: [mm] | 385 |

| Spindle speeds: [rpm] | 4.500 |

| Tailstock | |

| Travel: | |

| X-Axis: [mm] | 255 |

| Z-Axis: [mm] | 800 |

| Rapid motion: (X/Z) [m/min] | 30 |

| Amount of turrets: | 1 |

| Tool: | VDI 30 |

| Tool capacity: | 12 |

| Equipment: | |

| Chip conveyor | |

| Cooling pumps | |

| 3-jaw chuck [mm] | 250 |

Used CNC lathe DMG NEF 400

| CNC - lathe machine | |

| Machine type: | DMG NEF 400 V1 |

| Control: | Siemens 840 D ShopTurn |

| Year: | 2012 |

| SPECIFICATIONS: | |

| Between centers: [mm] | 805 |

| Max. turning length: [mm] | 650 |

| Turningdiameter: [mm] | 350 |

| Max. swing over bed: [mm] | 385 |

| Spindle speeds: [rpm] | 4.500 |

| Tailstock | |

| Travel: | |

| X-Axis: [mm] | 255 |

| Z-Axis: [mm] | 800 |

| Rapid motion: (X/Z) [m/min] | 30 |

| Amount of turrets: | 1 |

| Tool: | VDI 30 |

| Tool capacity: | 12 |

| Equipment: | |

| Chip conveyor | |

| Cooling pumps | |

| 3-jaw chuck [mm] | 250 |

DMG NEF 400 – High-Performance Turn-Mill Center for Maximum Precision

The DMG NEF 400 is a modern CNC turning center that allows both turning and milling in a single setup. With high precision and flexibility, it is ideal for medium-sized workpieces and complex components across various industries.

Key Technical Data

The machine can handle workpieces up to 400 mm in diameter and 600 mm in length. The main spindle reaches speeds of up to 6,000 rpm with a power of approximately 22 kW. The C-axis allows precise multi-angle machining, while the X and Z axes ensure fast and accurate positioning. The tool turret typically holds 12–24 tools, optimized for short setup times.

Control is via proven systems such as Heidenhain iTNC 530 or Siemens 840D / CELOS. With repeatability in the range of a few microns, the NEF 400 meets the highest standards for precision and quality.

Key Features & Advantages

The compact design allows easy integration into existing production environments. Reinforced machine beds provide high stiffness and vibration damping. Optional counter spindle, Y-axis, or B-axis can extend machining capabilities. The machine features short cycle times, high dynamics, and low energy consumption. Automation solutions and probing options complete the package.

Applications & Industries

The DMG NEF 400 is particularly suitable for:

- Mechanical engineering – complex turning and milling components, assemblies

- Automotive – transmission parts, shafts, prototypes, and series components

- Aerospace – high-precision components, small to medium-sized workpieces

- Medical technology – implants, instruments with high surface quality

- Energy & turbine industry – medium-diameter parts with complex geometry

Buying a Used DMG NEF 400 – An Attractive Option

To reduce investment costs, the market for used DMG NEF 400 machines offers interesting options. Well-maintained machines with documented running hours are often available.

When purchasing, attention should be paid to the condition of the main spindle, tool changer, and control version. A reliable dealer and optional service contract can significantly enhance the economic value of a used machine.

Alternatives to the DMG NEF 400

Within the DMG MORI portfolio, the following alternatives are available:

- DMG MORI NEF 320 – compact CNC turning machine for smaller workpieces with high precision

- DMG MORI NEF 600 – larger model for workpieces with greater diameter and length

- DMG MORI CTX 410 / CTX 500 – flexible turning machines for various workpiece sizes