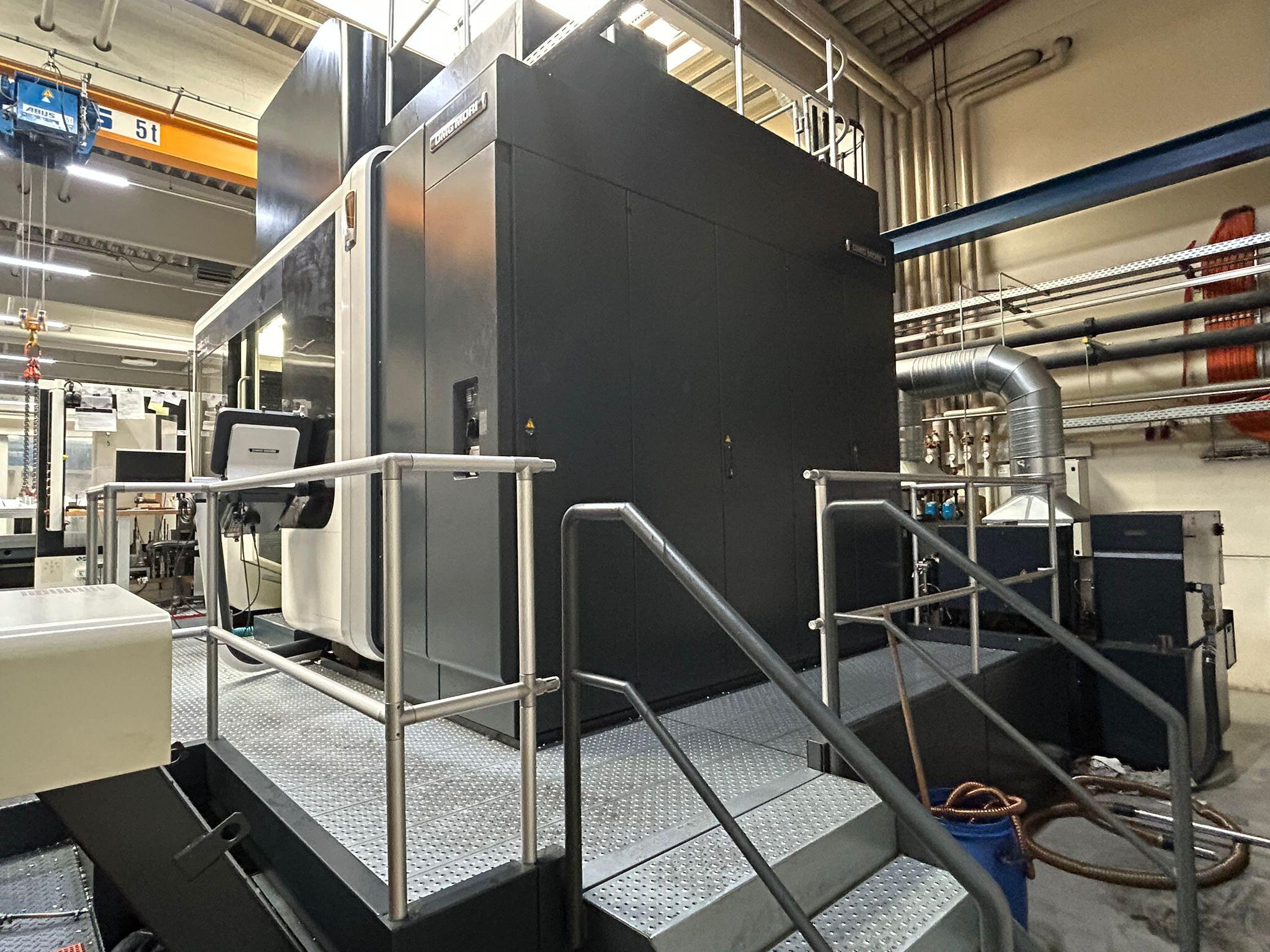

SOLD: DMG Mori DMC 210 U RS 5 Milling machine

Universal machining center

DMG Mori DMC 210 U RS 5 buy used

| Universal machining center | |

| Machine type: | DMG Mori DMC 210 U RS 5 |

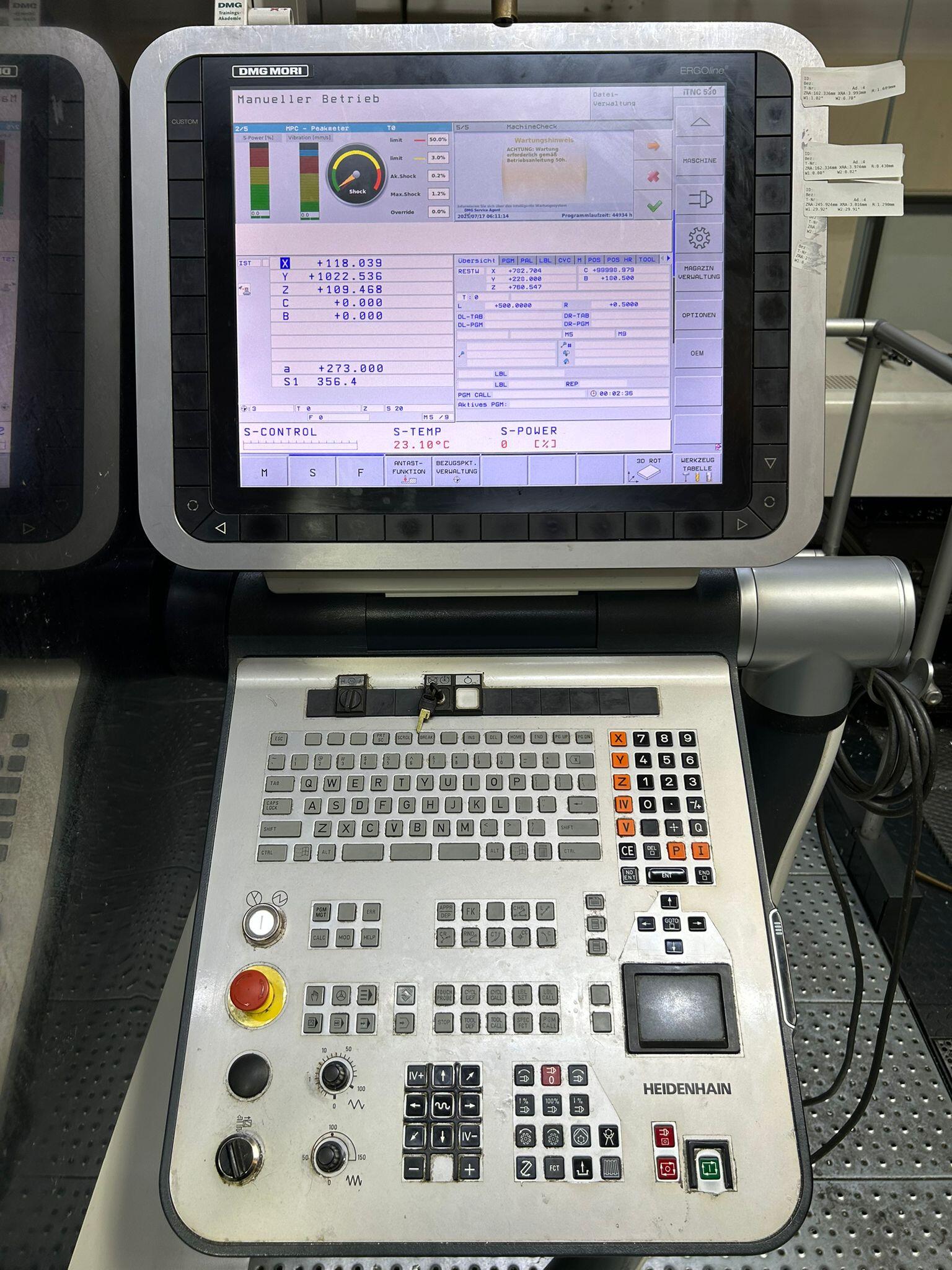

| Control: | Heidenhain iTNC 530 HSCI |

| Year: | 2015 |

| SPECIFICATIONS: | |

| X-Axis: [mm] | 2.100 |

| Y-Axis: [mm] | 1.800 |

| Z-Axis: [mm] | 1.250 |

| Spindle speeds: [rpm] | 20 - 18.000 |

| Spindle power: [kW] | 35 |

| Tool: | HSK 63 |

| Tool capacity: | 120 |

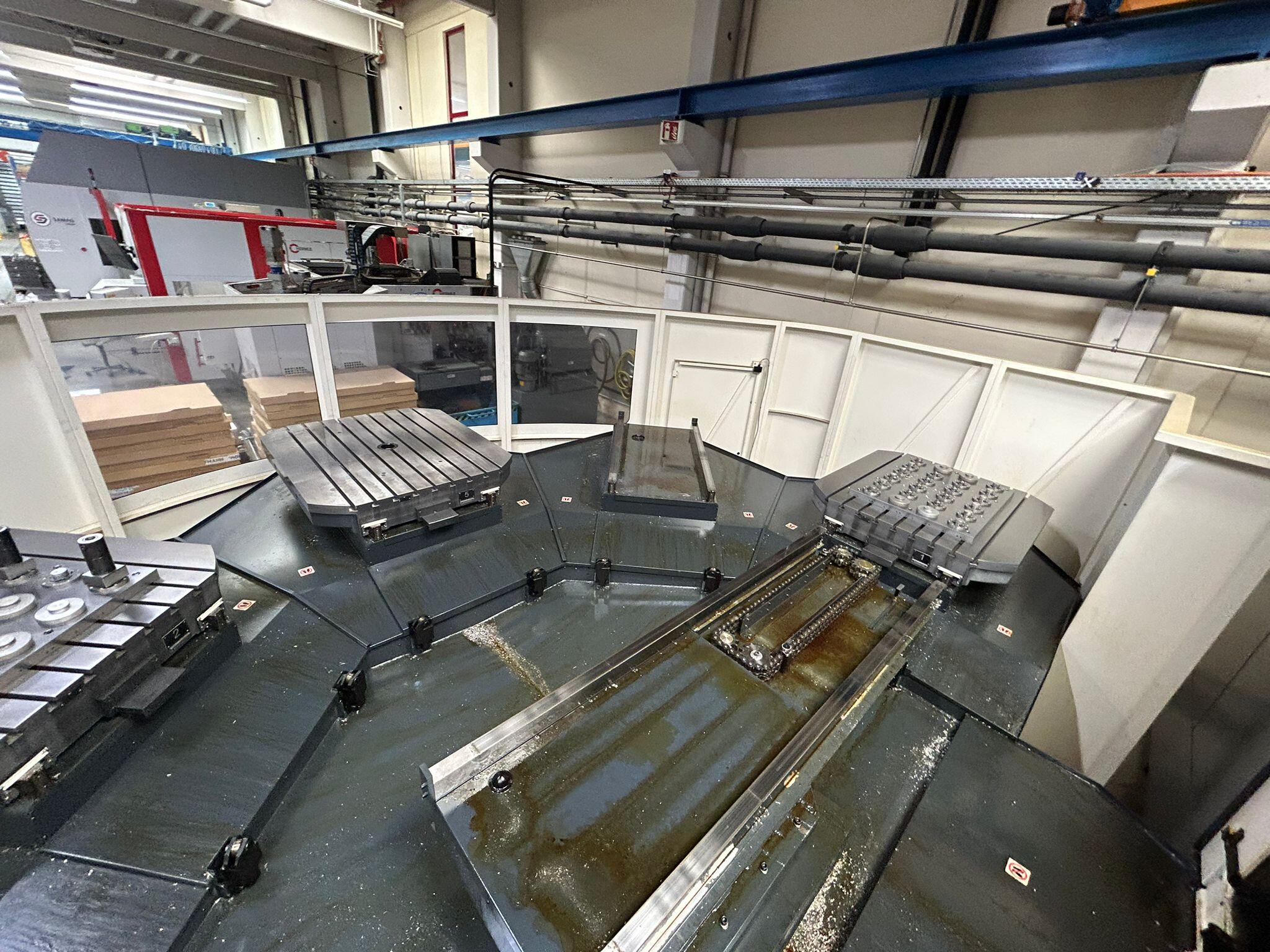

| Amount of paletts: | 5 |

| NC rotary table | |

| C-Axis | 0,001° |

| Palett size: [mm] | 1.700 x 1.400 |

| Max. Table Load: [kg] | 8.000 |

| Equipment: | |

| Chip conveyor | |

| Internal cooling: [bar] | 80 |

| Cooling tank: [l] | 980 |

| Tool setter | Blum Laser |

| Caliper | Heidenhain TS649 |

| Chip rinsing pistol | |

| Oil mist separator | |

| Palett system | RS 5 |

| MPC Machine Protection Control | |

| Temperiereinrichtung | |

| Electronical handwheel | |

| Schmierung Drehdurchführung | |

DMG Mori DMC 210 U RS 5 buy used

| Universal machining center | |

| Machine type: | DMG Mori DMC 210 U RS 5 |

| Control: | Heidenhain iTNC 530 HSCI |

| Year: | 2015 |

| SPECIFICATIONS: | |

| X-Axis: [mm] | 2.100 |

| Y-Axis: [mm] | 1.800 |

| Z-Axis: [mm] | 1.250 |

| Spindle speeds: [rpm] | 20 - 18.000 |

| Spindle power: [kW] | 35 |

| Tool: | HSK 63 |

| Tool capacity: | 120 |

| Amount of paletts: | 5 |

| NC rotary table | |

| C-Axis | 0,001° |

| Palett size: [mm] | 1.700 x 1.400 |

| Max. Table Load: [kg] | 8.000 |

| Equipment: | |

| Chip conveyor | |

| Internal cooling: [bar] | 80 |

| Cooling tank: [l] | 980 |

| Tool setter | Blum Laser |

| Caliper | Heidenhain TS649 |

| Chip rinsing pistol | |

| Oil mist separator | |

| Palett system | RS 5 |

| MPC Machine Protection Control | |

| Temperiereinrichtung | |

| Electronical handwheel | |

| Schmierung Drehdurchführung | |

DMG MORI DMC 210 U RS 5 – Compact 5-Axis Machining Center for Precise Manufacturing

The DMG MORI DMC 210 U RS 5 is a high-performance 5-axis machining center, specifically designed for small to medium-sized workpieces. Its compact design, combined with high dynamics and precision, makes it ideal for demanding manufacturing tasks across various industries.

Technical Specifications of the DMC 210 U RS 5 at a Glance

The machine offers travels of approximately 550 mm in X, 500 mm in Y, and 500 mm in Z. The workspace can accommodate workpieces up to 600 mm in diameter, 450 mm in height, and 400 kg in weight. The core of the machine is the powerful HSK-A63 spindle system, with speeds up to 20,000 rpm and 20 kW of power. The machine is standardly equipped with a chain magazine for up to 60 tools.

The NC swivel table allows precise simultaneous 5-axis machining and is operated via proven controls such as Heidenhain iTNC 640 or Siemens 840D / CELOS. With positioning accuracy of 4–5 µm, options for internal cooling, chip conveyors, and probes, the DMC 210 U RS 5 meets the highest standards for precision and process reliability.

Key Features & Advantages

The compact design saves space (approx. 6–7 m²) and offers easy access to the workspace thanks to large door openings. The cast bed provides high stiffness, while the axis guides and ball screws ensure precise and stable machining. Automation options can be integrated, making the machine attractive for series production.

Applications & Industries

The DMC 210 U RS 5 is especially suitable for:

- Tool and mold making – complex freeform surfaces, mechatronic molds

- Aerospace – precision components with tight tolerances

- Automotive – prototypes, series components, transmission parts

- Medical technology – implants and instruments requiring high surface quality

- Mechanical and plant engineering – components and assemblies for 5-axis machining

Buying a Used DMC 210 U RS 5 – An Attractive Option

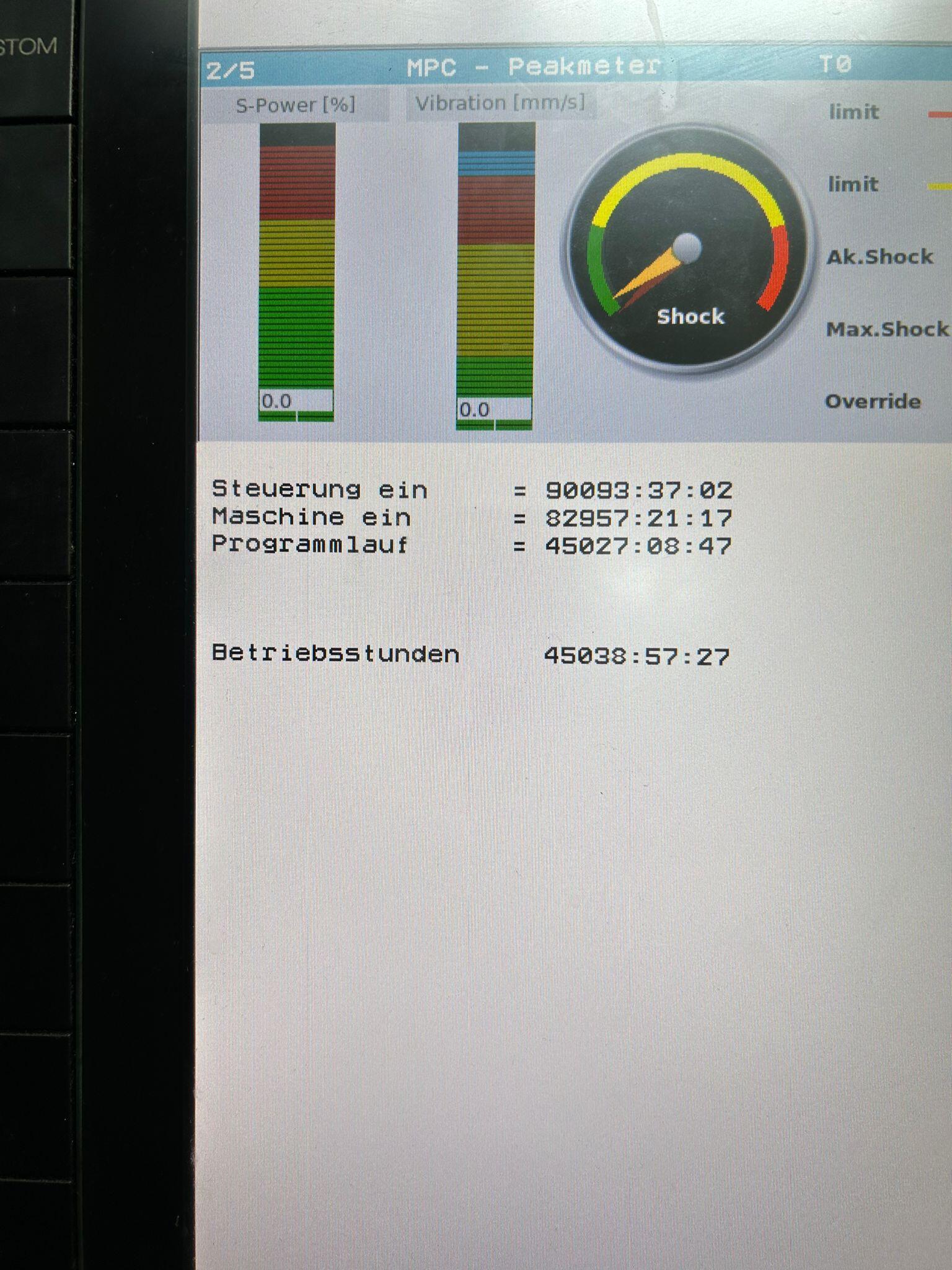

Those looking to reduce investment costs for a new 5-axis machining center will find an interesting option in the market for used DMC 210 U RS 5 machines. Well-maintained units are often available, including service history and documented machine hours.

When purchasing, pay attention to spindle hours, tool changer condition, and control version. With a reliable dealer and an optional service contract, a used machine can be a very economical alternative to buying new.

Alternatives to the DMC 210 U RS 5

Those seeking alternatives will find suitable 5-axis solutions both in DMG MORI’s portfolio and from other manufacturers. Within the DMC series, models with larger or smaller travels are available, allowing flexible selection depending on workpiece size and performance requirements.

Other manufacturers offering similar 5-axis solutions include:

- Hermle C-Series – especially popular in tool and mold making, high precision

- Mazak Variaxis / Integrex – flexible 5-axis and multitasking machines

- GROB – stable and precise 5-axis machining centers

- Okuma MU-Series – robust machines with advanced thermal compensation, ideal for heavy workpieces

The choice of the right machine depends on individual requirements for space, precision, automation, and investment budget.