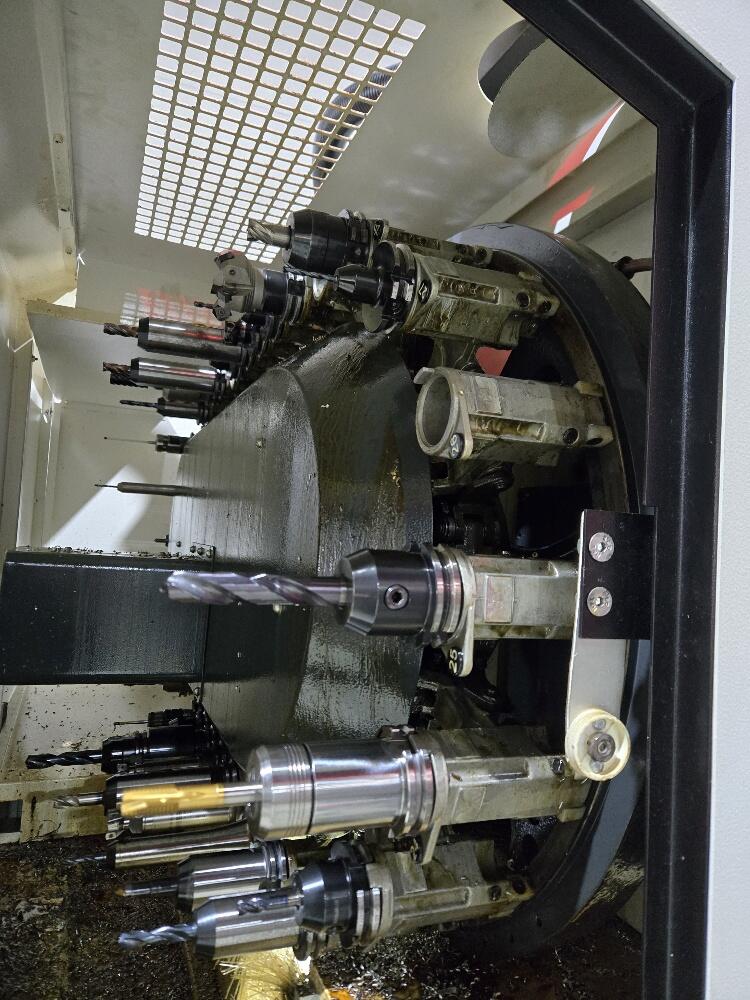

DMG Mori CMX 70 U 3+2 – Flexible Universal Machining Center

The DMG Mori CMX 70 U 3+2 is a high-precision universal machining center, specifically designed for complex workpieces using 3+2-axis technology. Its robust construction and advanced control system provide an excellent solution for demanding manufacturing tasks.

Technical Data of DMG Mori CMX 70 U 3+2

The machine offers generous travel ranges of 750 mm in the X-axis, 600 mm in the Y-axis, and 520 mm in the Z-axis, easily accommodating medium-sized workpieces. The table measures 800 x 620 mm and can handle parts weighing up to 350 kg. The spindle is powered by a 13 kW motor, providing speeds of up to 12,000 rpm and a torque of 82 Nm. Tool holding is via SK 40, with 32 tool positions for maximum flexibility. The B- and C-axes allow tilt angles from -10° to +95° and 360°, respectively, making the machine suitable for a wide range of operations. Rapid traverse rates of 30 m/min in all axes ensure high productivity.

3+2-Axis Machining – What Does It Mean?

3+2-axis machining refers to a method where the workpiece is positioned in two rotary axes (B and C), while machining is performed along the three linear axes (X, Y, Z). This allows complex geometries to be machined on multiple sides in a single setup, without requiring simultaneous 5-axis motion.

Advantages of 3+2-Axis Machining

- Cost Efficiency: Less demanding control technology compared to full 5-axis simultaneous machining.

- Easy Programming: Clear, structured machining cycles enable precise operation.

- Reduced Complexity: Easier setup and maintenance.

Difference from 5-Axis Simultaneous Machining

Unlike 5-axis simultaneous machining, where all five axes move at the same time, 3+2 machining proceeds in discrete steps. The workpiece is repositioned manually or automatically for each new machining angle before the operation continues. This provides an efficient and cost-effective alternative for many applications, while keeping programming and setup simpler.

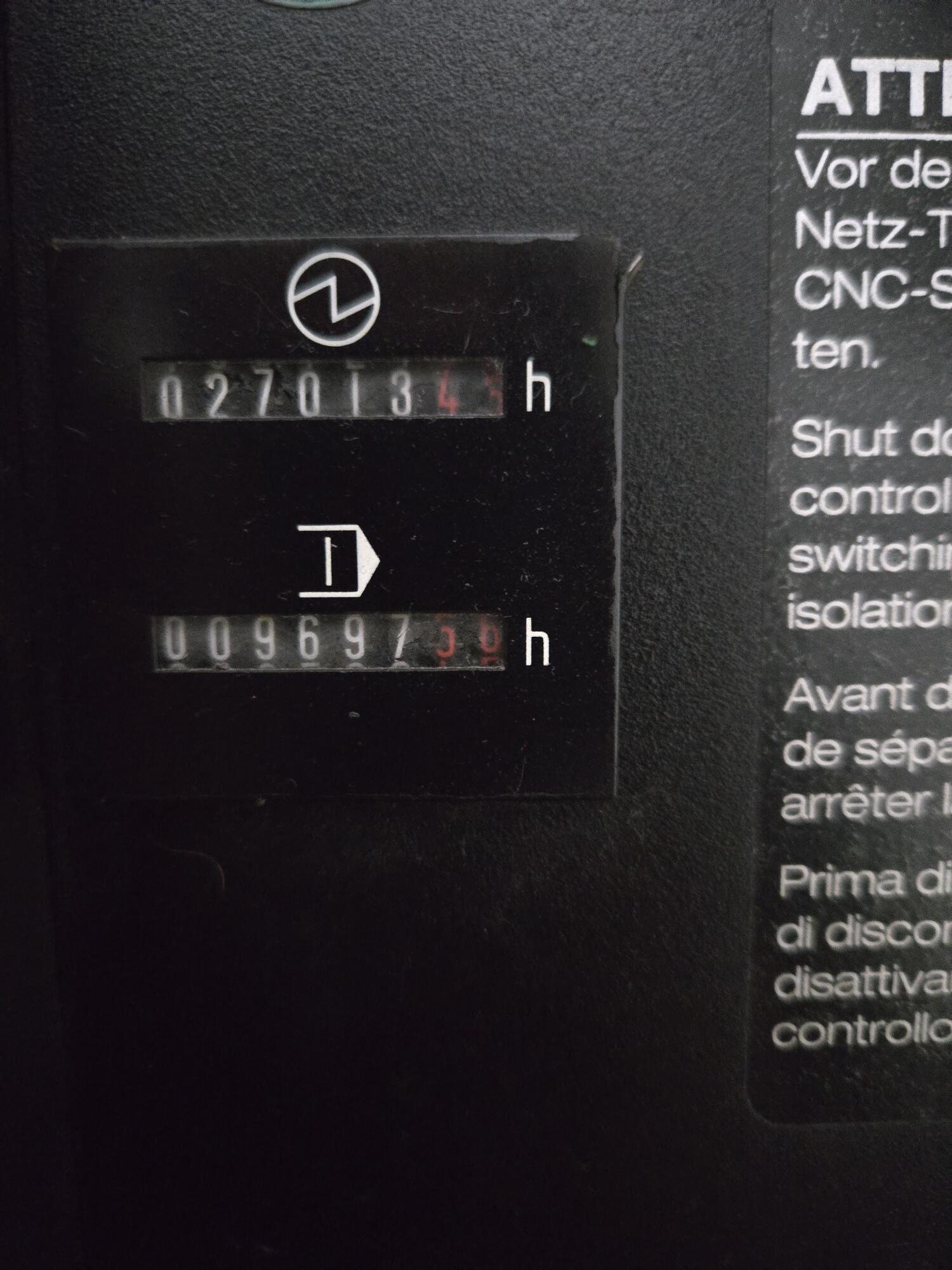

Service & Maintenance

For long-term, reliable operation of the DMG Mori CMX 70 U 3+2, regular maintenance is essential. More information and service options are available on our service page.