Used Mori Seiki NH 8000

Horizontal machining center

Milling machine Mori Seiki NH 8000 used

| Horizontal machining center | |

| Machine type: | Mori Seiki NH 8000 DCG |

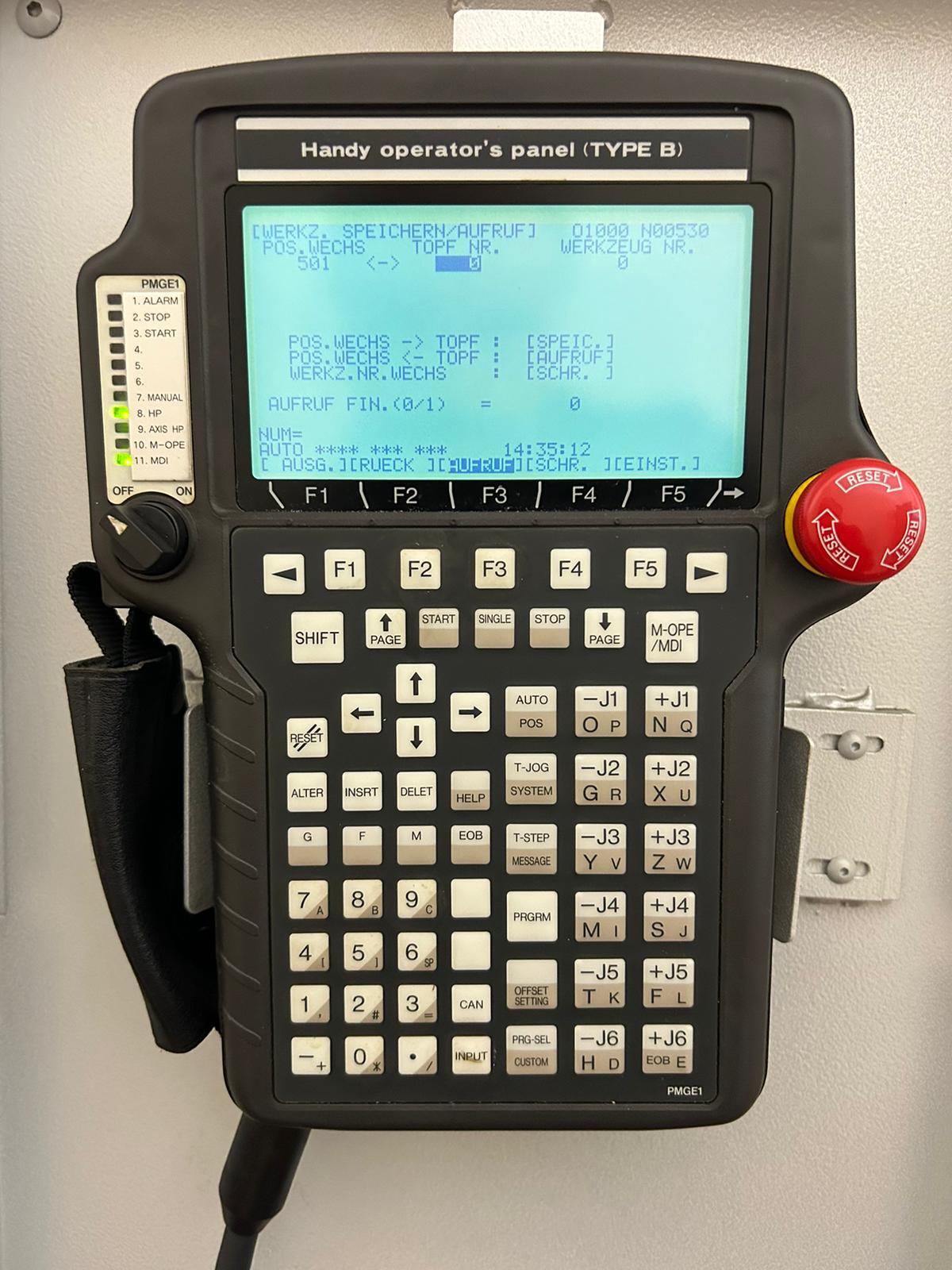

| Control: | Fanuc 18 imb + Mapps 2 |

| Year: | 2005 |

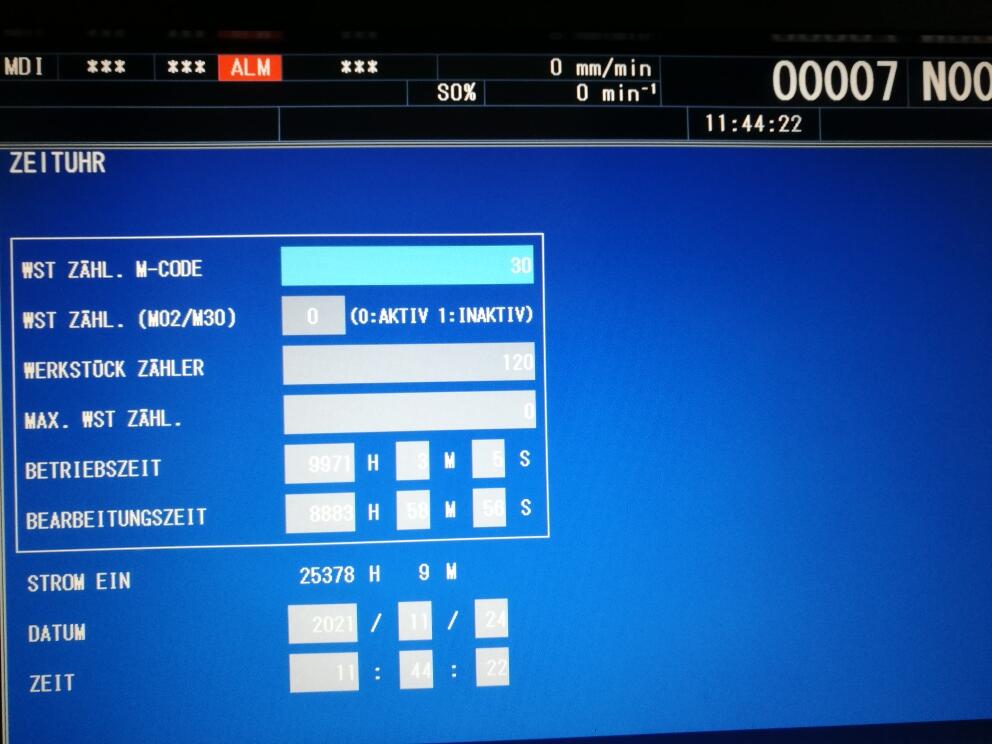

| Working hours: [h] | !!! 9.971 !!! |

| SPECIFICATIONS: | |

| Travel: | |

| X-Axis: [mm] | 1.400 |

| Y-Axis: [mm] | 1.200 |

| Z-Axis: [mm] | 1.200 |

| B-Axes | 0,001° |

| Rapid motion: (X/Y/Z) [m/min.] | 50 |

| Spindle speeds: [rpm] | 10.000 |

| Spindle power: [kW] | 30 / 25 |

| Tool: | BT 50 |

| Toolchanger | |

| Tool capacity: | 140 |

| Palett system | |

| Amount of paletts: | 2 |

| Palett size: [mm] | 800 x 800 |

| Machine weight: [kg] | 32.000 |

| Req. space (LxBxH): [m] | 9,200 x 4,900 x 3,920 |

| Equipment: | |

| Internal cooling: [bar] | |

| Chip conveyor | |

| High pressure pumps |

Milling machine Mori Seiki NH 8000 used

| Horizontal machining center | |

| Machine type: | Mori Seiki NH 8000 DCG |

| Control: | Fanuc 18 imb + Mapps 2 |

| Year: | 2005 |

| Working hours: [h] | !!! 9.971 !!! |

| SPECIFICATIONS: | |

| Travel: | |

| X-Axis: [mm] | 1.400 |

| Y-Axis: [mm] | 1.200 |

| Z-Axis: [mm] | 1.200 |

| B-Axes | 0,001° |

| Rapid motion: (X/Y/Z) [m/min.] | 50 |

| Spindle speeds: [rpm] | 10.000 |

| Spindle power: [kW] | 30 / 25 |

| Tool: | BT 50 |

| Toolchanger | |

| Tool capacity: | 140 |

| Palett system | |

| Amount of paletts: | 2 |

| Palett size: [mm] | 800 x 800 |

| Machine weight: [kg] | 32.000 |

| Req. space (LxBxH): [m] | 9,200 x 4,900 x 3,920 |

| Equipment: | |

| Internal cooling: [bar] | |

| Chip conveyor | |

| High pressure pumps |

Request price for Mori Seiki NH 8000:

Mori Seiki NH 8000 – High-Performance Horizontal Machining Center

Mori Seiki NH 8000 is a high-precision horizontal machining center designed specifically for economical series production and complex components. The machine impresses with its stability, accuracy, and dynamic performance, making it suitable for large workpieces and demanding 3D machining tasks.

Technical Specifications and Equipment of the Mori Seiki NH 8000

The NH 8000 features generous travel ranges in all axes and a powerful main spindle with high torque reserve, ensuring consistent machining quality even with heavy workpieces. Precision linear guides and high-dynamic axis drives allow fast machining cycles without sacrificing accuracy. The user-friendly control enables easy programming of complex components. Additional options such as pallet changers, integrated cooling, probes, and chip conveyors support efficient production and short setup times.

Key Features & Advantages

The machine excels with thermal stability and high rigidity, delivering precise results even during long machining cycles and with large workpieces. The horizontal design facilitates chip removal and reduces wear, while automation options such as pallet handling or robot integration further increase productivity. The NH 8000 can process a wide range of materials—from aluminum to steel to high-strength alloys—and is suitable for both prototypes and series production.

Manufacturer Mori Seiki – Precision from Japan

Mori Seiki, now part of DMG MORI, is a leading global manufacturer of machine tools. The company is known for top-notch precision, innovative technologies, and durable machines. With decades of experience, strict quality control, and a focus on efficient production solutions, Mori Seiki is a reliable choice for series production, complex components, and high-precision applications.

Alternatives to the Mori Seiki NH 8000

More horizontal machining centers can be found here: Horizontal Machining Centers.

Applications

The NH 8000 is used across various industries, including mechanical engineering, automotive, aerospace, and energy/turbine manufacturing. Typical applications include machining gears, housings, shafts, and complex 3D components requiring high precision and repeatability.

Service & Maintenance

Regular service is essential for the long-term reliable operation of the Mori Seiki NH 8000. Information on our service offerings can be found on our service page.